SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

30

JOHNSON CONTROLS

The metallic disk is mounted at the factory between two special flanges. The flanges have

a knife-edge that perforates a special flange on the disk to create an airtight seal.

The outer flange of the disk holder has a plastic pipe stub supplied by the factory for

shipping purposes. The PLASTIC stub must be removed! Refer to

Rupture Disk Discharge Piping Material

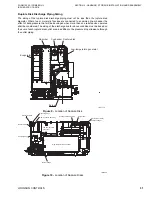

ANSI/ASHRAE 15-2001 calls for the relief piping material to be compatible with the

refrigerant in the system. The refrigerant is de-ionized water that could exceed 200°F

(93.3°C) in some cases. Johnson Controls recommends using schedule 40 steel pipe

for the rupture disk discharge line material.

Rupture Disk Discharge Piping Construction

For the piping material, Johnson Controls recommends carbon steel. The relief piping must

be fabricated and constructed in accordance with piping best practices. Follow any local

codes (if applicable) governing the rupture disk discharge relief piping. Due to the high

temperatures of an absorption unit during operation, and the expansion and contraction

associated with this, the rupture disk vent piping must have a flexible connection between

the rupture disk outlet and the relief piping. The installing contractor must supply the

flexible connection and the relief piping.

Piping supports must be spaced according to the pipe material, size and temperature.

Figure 8 -

Plastic Pipe Stub

CAUTION: Liquid coming out of the rupture disk could be in excess of 200°F (93.3°C)!

NOTE: Do not loosen the bolts around the flange or remove the disk from the holder. If

the disk is removed for any reason, it must be replaced with a new one!

NOTE: At no time should there be any weight or moment arm forces imposed on the

flanges of the rupture disk!

6RGYZOIVOVKYZ[H

8[VZ[XKJOYQ