FORM 150.75-NM2

21

YORK INTERNATIONAL

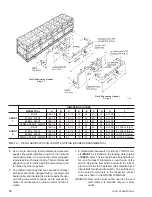

MASTER MODULE WIRING DIAGRAM

FIG. 15

MASTER MODULE ELEMENTARY DIAGRAM (Contd)

CAUTION: No Controls (relays, etc.)

should be mounted in the

Smart Panel enclosure or

connected to power sup-

plies in the control panel.

Additionally, control wiring

not connected to the Smart

Panel should not be run

through the cabinet. This

could result in nuisance

faults.

CAUTION: Any inductive devices (re-

lays) wired in series with

the flow switch for start/

stop, into the Alarm cir-

cuitry, or pilot relays for

pump starters wired

through motor contactor

auxiliary contacts must be

suppressed with YORK

P/N 031-00808-000 sup-

pressor across the relay/

contact coil which acti-

vates the contacts.

Any contacts connected to

flow switch inputs or BAS

inputs on terminals 13-19

of TB3, or any other termi-

nals, must be suppressed

with a YORK P/N 031-

00808 suppressor across

the relay/contactor coil

which activates the con-

tacts.

CAUTION: Control wiring connected

to the control panel should

never be run in the same

conduit with power wiring.

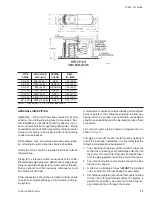

CONTROL

MIN

MAX

NON-FUSED

UNIT

POWER

CIRCUIT

DUAL

DISC. SW.

VOLTAGE

SUPPLY AMPACITY

ELEMENT

SIZE

FUSE SIZE

All

Models w/o 115-1-50/60

20A

20A, 250A

30A, 240A

Transformers

CONTROL POWER SUPPLY

LD01928