22

YORK INTERNATIONAL

FORM 201.19-NM6 (804)

DX EVAPORATOR AND STARTER OPTIONS

300 PSIG (21 bar) Waterside Design Working

Pressure

–

The DX evaporator waterside is designed

and con struct ed for 300 PSIG (21 bar) working pressure.

(Factory-mounted)

1-1/2" (38 mm) Insulation –

Double thickness in su -

la tion provided for enhanced effi ciency.

Flange Accessory

–

Consists of raised face fl anges to

convert grooved water nozzles to fl anged evaporator

connections. Includes companion flanges for field-

mount ing. See Page 31.

Remote DX Evaporator

– Includes the main con-

dens ing unit less the evaporator, re frig er ant and liquid

line de vic es. The insulated evaporator and fi eld acces-

sory kits per re frig er ant circuit are sup plied separately.

The condensing unit is shipped with a nitrogen holding

charge and the evaporator is shipped with a ni tro gen

hold ing charge.

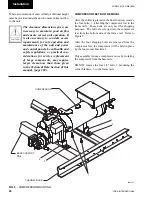

Flow Switch Accessory

– Johnson Controls model

F61MG-1C Vapor-proof SPDT, NEMA 4X switch, 150

PSIG (10 bar) DWP, -20°F to 250°F (-29°C to 121°C),

with 1" NPT (IPS) con nec tion for upright mounting in

horizontal pipe. A fl ow switch must be fi eld installed

with each unit. Optional 300 PSIG switch available.

Star-Delta Compressor Motor Starter

– Provides ap-

proximately 65% reduced inrush current compared to

across-the-line start (Factory-mounted).

UNIT ENCLOSURE OPTIONS

Wire enclosure

–

Heavy gauge welded wire mesh

guards mounted on the exterior of the unit (Factory- or

fi eld-mounted).

Louvered panels and wired guards

–

Louvered pan-

els mounted over the exterior condenser coil faces, and

heavy gauge welded wire mesh guards mounted around

the bottom of the unit (Factory- or fi eld-mounted).

Louvered panels (condenser coils only)

–

Lou vered

panels are mounted over the exterior condenser coil faces

on the sides of the unit to visually screen and pro tect the

coils (Factory- or fi eld-mounted).

Louvered panels (full unit) enclosure

–

Louvered

panels over condenser coils and around the bottom of

the unit (Factory- or fi eld-mounted).

FAN OPTIONS

High static fans:

Fans and motors suitable for High

External Static conditions to 100 Pa.

SOUND REDUCTION OPTIONS

Low speed fans

–

Reduced RPM fan motors and al ter -

na tive fan selection for low noise applications.

Compressor sound enclosures

–

Acoustically

treated metal compressor enclosures.

VIBRATION ISOLATION

Neoprene pad isolation

–

Recommended for normal

installations. (Field-mounted)

1" (25 mm) spring isolators

–

Level adjustable, spring

and cage type isolators for mounting under the unit base

rails (Field-mounted).

2" (51 mm) seismic spring isolators

–

Restrained

Spring-Flex Mountings incorporate welded steel hous-

ing with vertical and horizontal limit stops. Housings de-

signed to withstand a minimum 1.0 g accelerated force in

all directions to 2" (51 mm). Level ad just able, de fl ec tion

may vary slightly by application. (Field- mount ed).

Product Description

Summary of Contents for YCAS

Page 43: ...43 YORK INTERNATIONAL FORM 201 19 NM6 804 5 This page intentionally left blank...

Page 45: ...45 YORK INTERNATIONAL FORM 201 19 NM6 804 6 This page intentionally left blank...

Page 65: ...65 YORK INTERNATIONAL FORM 201 19 NM6 804 7 LD09359 Electronic Panel 035 19205 104 Rev A...

Page 81: ...81 YORK INTERNATIONAL FORM 201 19 NM6 804 LD09378 CONNECTION WIRING DIAGRAM Electronic Panel...

Page 91: ...91 YORK INTERNATIONAL FORM 201 19 NM6 804 This page intentionally left blank...

Page 147: ...147 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...

Page 205: ...205 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...