JOHNSON CONTROLS

4

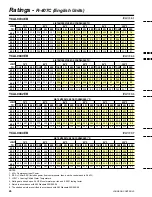

NOTES:

1. kW

o =.

Unit kW Cooling Capacity Output

2

. kW

i =

Compressor kW Input

3. COP = Coefficient of Performance (Based upon compressor and fan input kW)

4. LCWT = Leaving Chilled Water Temperature

5. Ratings based upon 0.15L/s cooler water per kW

Ratings -

R-407C (SI Units)

YCAL0050EB

COP=4.03

YCAL0060EB

COP=4.26

YCAL0064EB

COP=4.01

YCAL0070EB

COP=4.05

AIR TEMPERATURE ON - CONDENSER (°C)

LCWT

(°C)

25°C

30°C

35°C

40°C

45°C

50°C

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

5.0

178.1 48.7

3.3

169.3 54.2

2.8

160.1 60.1

2.4

150.7 66.7

2.1

105.8 50.7

1.9

71.2

36.2

1.7

6.0

184.2 49.1

3.4 175°F 54.5

2.9

165.5 60.6

2.5

155.9 67.1

2.1

109.5 51.0

1.9

73.7

36.5

1.8

7.0

190.3 49.4

3.5

180.9 54.9

3.0

171.1 61.0

2.6

161.2 67.6

2.2

113.4 51.3

2.0

76.6

36.6

1.8

8.0

196.5 49.8

3.6

186.8 55.3

3.1

176.8 61.4

2.6

166.6 68.1

2.3

117.5 51.6

2.1

79.4

36.7

1.9

9.0

202.9 50.2

3.6

192.9 55.7

3.2

182.6 61.8

2.7

172.1 68.6

2.3

121.6 51.9

2.1

82.3

36.9

1.9

10.0 209.3 50.6

3.7

199.1 56.1

3.2

188.5 62.3

2.8

177.7 69.1

2.4

125.8 52.2

2.2

85.2

37.1

2.0

11.0 216.0 51.1

3.8

205.4 56.6

3.3

194.6 62.8

2.9

183.5 69.6

2.4

130.1 52.5

2.2

88.3

37.2

2.1

AIR TEMPERATURE ON - CONDENSER (°C)

LCWT

(°C)

25°C

30°C

35°C

40°C

45°C

50°C

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

5.0

196.2 50.8

3.5

187.6 56.1

3.0

178.0 62.4

2.6

168.4 69.1

2.3

158.1 76.8

1.9

79.2

38.3

1.8

6.0

202.9 51.1

3.6

193.3 56.8

3.1

183.4 63.2

2.7

173.3 70.1

2.3

162.7 77.9

2.0

82.2

38.4

1.9

7.0

209.8 51.4

3.7

199.9 57.1

3.2

189.7 63.5

2.7

179.2 70.5

2.4

168.4 78.2

2.0

85.2

38.5

1.9

8.0

216.7 51.7

3.8

206.5 57.5

3.3

196.0 63.9

2.8

185.2 70.9

2.4

174.2 78.6

2.1

88.2

38.7

2.0

9.0

223.8 52.0

3.9

213.3 57.8

3.4

202.5 64.2

2.9

191.4 71.4

2.5

180.0 79.1

2.1

91.4

38.8

2.1

10.0 230.9 52.4

4.0

220.2 58.2

3.5

209.1 64.7

3.0

197.7 71.8

2.6

185.9 79.7

2.2

94.7

38.9

2.1

11.0 238.2 52.7

4.1

227.2 58.6

3.5

215.8 65.1

3.1

204.1 72.3

2.6

104.5 35.1

2.6

98.0

39.1

2.2

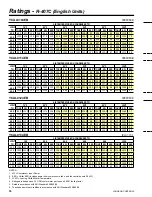

AIR TEMPERATURE ON - CONDENSER (°C)

LCWT

(°C)

25°C

30°C

35°C

40°C

45°C

50°C

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

5.0

219.1 59.7

3.3

207.5 66.4

2.8

195.8 73.8

2.4

183.9 81.9

2.1

172.3 90.5

1.8

113.0 61.6

1.7

6.0

226.5 60.1

3.4

214.6 66.9

2.9

202.5 74.3

2.5

190.4 82.4

2.1

178.4 91.2

1.8

116.9 62.2

1.7

7.0

233.9 60.5

3.5

221.7 67.3

3.0

209.3 74.9

2.6

196.9 83.0

2.2

155.5 72.0

2.0

121.2 62.5

1.8

8.0

241.5 61.0

3.6

229.1 67.8

3.1

216.3 75.4

2.6

203.6 83.6

2.3

161.0 72.4

2.0

125.7 62.8

1.8

9.0

249.4 61.5

3.7

236.6 68.3

3.2

223.4 76.0

2.7

210.3 84.2

2.3

166.6 72.8

2.1

130.3 63.1

1.9

10.0 257.4 61.9

3.7

244.1 68.8

3.2

230.7 76.5

2.8

217.3 84.9

2.4

172.4 73.2

2.2

135.0 63.4

1.9

11.0 265.5 62.5

3.8

251.9 69.4

3.3

238.2 77.1

2.8

224.4 85.5

2.4

178.3 73.7

2.2

139.8 63.7

2.0

AIR TEMPERATURE ON - CONDENSER (°C)

LCWT

(°C)

25°C

30°C

35°C

40°C

45°C

50°C

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

kWo

kWi

COP

5.0

244.4 65.2

3.4

231.7 72.5

2.9

218.6 80.7

2.5

205.2 89.5

2.1

191.8 98.9

1.8

125.9 67.3

1.7

6.0

252.6 65.7

3.5

239.6 73.0

3.0

226.1 81.2

2.6

212.3 90.1

2.2

198.7 99.5

1.9

130.6 67.7

1.8

7.0

261.1 66.2

3.6

247.6 73.5

3.1

233.7 81.8

2.6

219.7 90.7

2.3

205.7 100.2

1.9

135.4 68.1

1.8

8.0

269.7 66.7

3.7

255.8 74.1

3.2

241.6 82.3

2.7

227.2 91.3

2.3

212.9 100.9

2.0

139.5 69.1

1.8

9.0

278.5 67.2

3.8

264.2 74.6

3.2

249.6 82.9

2.8

234.8 92.0

2.4

220.2 101.7

2.0

144.7 69.4

1.9

10.0 287.5 67.8

3.9

272.8 75.2

3.3

257.8 83.6

2.9

242.6 92.7

2.4

160.5 63.1

2.3

150.0 69.8

2.0

11.0 296.7 68.4

3.9

281.6 75.8

3.4

266.2 84.2

2.9

250.7 93.4

2.5

166.2 63.4

2.4

155.5 70.1

2.0