Additionally, the slab should NOT be tied to the main building

foundations as noise due to vibration may be transmitted.

For ground level installations, precautions should be taken to

protect the unit from tampering and unauthorized persons from

injury. Screws on access panels will prevent casual tampering.

Further safety precautions such as a fenced enclosure or

locking devices on the panels may be advisable. Check local

authorities for safety regulations.

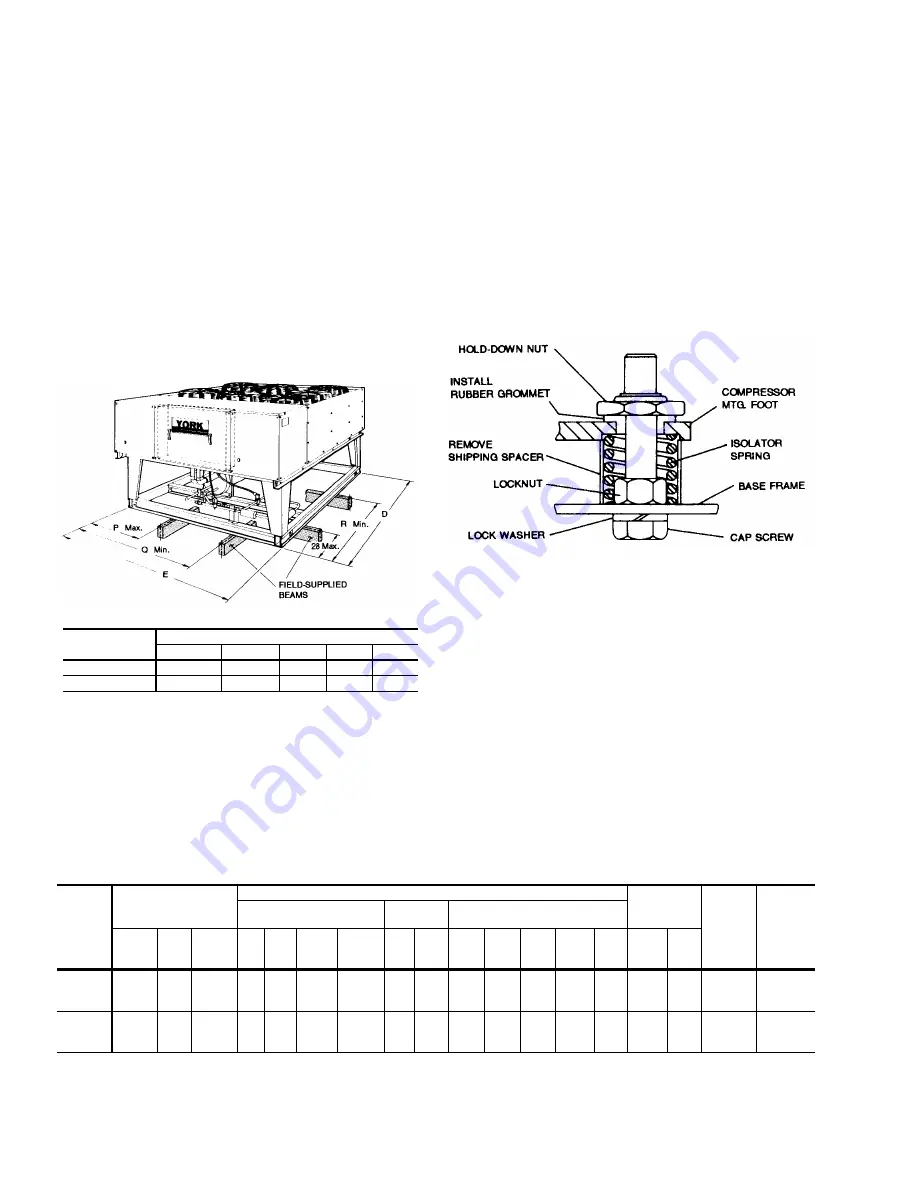

ROOFTOP LOCATIONS

Choose a spot with adequate structural strength to safely

support the entire weight of the unit and service personnel.

Care must be taken so as not to damage the roof. Consult the

building contractor or architect if the roof is bonded. The unit

must be mounted level on a minimum of two beams. The

beams should (1) be positioned perpendicular to the roof joists,

(2) extend beyond the dimensions of the section to distribute

the load on the roof, (3) be capable of supporting the weight of

the unit and (4) be positioned parallel to the longer base rails

of the unit OR parallel to the shorter base rails of the unit as

shown in Figure 2.

CLEARANCES

The units must be installed with sufficient clearance for air to

enter the condenser coil and not be recirculated after dis-

charge. Sufficient clearance must also be provided for service

access. Refer to the unit illustration in Figure 5 for minimum

clearances.

The area within the clearances and the area under the unit must

be kept clear of all obstructions that would impede free air flow

to the unit. In installations where low ambient operation is

intended and snow accumulation is expected, additional unit

height must be provided to insure full air flow.

COMPRESSOR HOLD-DOWN NUTS

For shipping, the compressor hold-down nuts are tightened,

drawing the compressor mounting feet down to the shipping

stops.

CAUTION: After the unit is in its final position, remove the

compressor hold-down nuts and shipping spac-

ers. Install rubber grommets (shipped in bag tied

to compressor). Replace the hold-down nuts and

tighten until they start to bind the rubber grom-

mets. Continue to tightened additional half turn.

See Figure 3.

DISCHARGE LINE HOLD-DOWN BRACKET

CAUTION: Do NOT remove the discharge line support brack-

ets located within the compressor compartment. It

reduces vibration during unit operation.

CHILLED LIQUID PIPING

The cooler inlet and outlet liquid connections are 3 inch nominal

pipe size. The connections are made with grooved ends de-

signed to accept Victaulic

grooved pipe couplings only. Re-

move the shipping caps and discard.

CAUTION: The liquid piping RETURNING to the chiller MUST

be attached to the cooler connection CLOSEST to

the compressor end of the unit. The liquid piping

LEAVING the cooler MUST be attached to the

cooler connection FURTHEST from the compres-

sor end of the unit. See Figure 5 for liquid inlet and

outlet connections.

FIG. 2 - SUPPORT BEAM LOCATIONS

Model

Dimensions (Inches)

D

E

P

Q

R

W1LC420

118-5/8

86-3/4

30

70

76

W1LC530

118-5/8

86-3/4

30

70

76

Model

Compressor

1

Condenser

Unit Weight

(Lbs.)

Oper.

Charge,

(R-22)

(Lbs.)

Cap.

Reduction

(%)

Fan (Propeller)

Fan

Motors

3

Coil

(Copper Tube - Aluminum Fin)

Nom.

Cap.

(Tons)

No.

of

Cyl.

Stages

of

Cap.

Qty.

2

Dia.

(In.)

Pitch

(Deg.)

Nom.

CFM

HP RPM

Face

Area

(Ft.

2

)

Rows

Deep

Rows

Wide

Tube

OD

(in.)

Fins

per

inch

Ship. Oper.

W1LC420

System 1

System 2

20

20

4

4

2

2

3

3

24

30

16,050

16,050

3/4 1075 30.0

30.0

3

3

36

36

3/8

12

3,380 3,480

26.0

26.0

25,50

75,100

W1LC530

System 1

System 2

20

30

4

6

2

2

3

4

24

30

14,400

19,400

3/4 1075 35.0

35.0

4

4

30

42

3/8

12

3,720 3,820

26.0

35.0

20,40

60,100

1

All compressors are semi-hermetic.

2

During low ambient conditions, the motor for one of these fans will operate at 450 RPM.

3

These PSC motors are directly connected to the condenser fans and have inherent protection, ball bearings and a 48 frame. Their rotation is clockwise when viewing the shaft end of

the motor.

TABLE 2 - PHYSICAL DATA

FIG. 3 - COMPRESSOR HOLD-DOWN NUTS

570.05-N4Y

4

Unitary Products Group