521149-UTG-C-0612

Johnson Controls Unitary Products

3

HORIZONTAL SIDEWALL VENTING

For applications where vertical venting is not possible, the only

approved method of horizontal venting is the use of an auxiliary

power vent. Auxilary power venters must be approved by CSA,

UL, or other recognized safety agencies. Follow all application

and installation details provided by the manufacturer of the

power vent.

FILTER PERFORMANCE

The airflow capacity data published in the “Blower Perfor-

mance” table shown represents blower performance WITHOUT

filters.

All applications of these furnaces require the use of field

installed air filters. All filter media and mounting hardware or

provisions must be field installed external to the furnace cabi-

net. DO NOT attempt to install any filters inside the furnace.

1. Air velocity through throwaway type filters may not exceed 300 feet per min-

ute (91.4 m/min). All velocities over this require the use of high velocity fil-

ters.

2. Do not exceed 1800 CFM using a single side return and a 16x25 filter. For

CFM greater than 1800, you may use two side returns or one side and the

bottom or one return with a transition to allow use of a 20x25 filter.

ACCESSORIES

Propane (LP) Conversion Kit -

1NP0347 - All Models

This accessory conversion kit may be used to convert natural

gas units for propane (LP) operation.

Side Return Filter Racks -

1SR0200 - All Models

1SR0302 - All Models

1SF0101 - All Models

Bottom Return Filter Racks -

1BR0514 or 1BR0614 - For 14-1/2” cabinets

1BR0517 or 1BR0617 - For 17-1/2” cabinets

1BR0521 or 1BR0621 - For 21” cabinets

1BR05xx series are galvanized steel filter racks. 1BR06xx are

pre-painted steel filter racks to match the appearance of the fur-

nace cabinet.

Masonry Chimney Kits -

For installations where these furnaces are vented using existing

or new lined masonry chimneys.

1CK0603

1CK0604

Combustible Floor Base Kit -

For installation of these furnaces in downflow applications

directly onto combustible flooring material, These kits are

required to prevent potential overheating situations. These kits

are also required in any applications where the furnace in

installed in a downflow configuration without an evaporator coil,

where the combustible floor base kit provides access for com-

bustible airflow.

1CB0514 - For 14-1/2” cabinets

1CB0517 - For 17-1/2” cabinets

1CB0521 - For 21” cabinets

High Altitude Pressure Switches -

For installation where the altitude is less than 5,000 feet it is not

required that the pressure switch be changed. For altitudes

above 5,000 feet, see kits below.

1PS3309

Thermostats

- Compatible thermostat controls are available

through accessory sourcing. For optimum performance and

installation, refer to the UPGNET “Low Voltage Wiring Diagram”

document to select and apply controls.

Single side return above 1800 CFM is approved as long as

the filter velocity does not exceed filter manufacturer’s rec-

ommendation and a transition is used to allow use on a

20x25 filter.

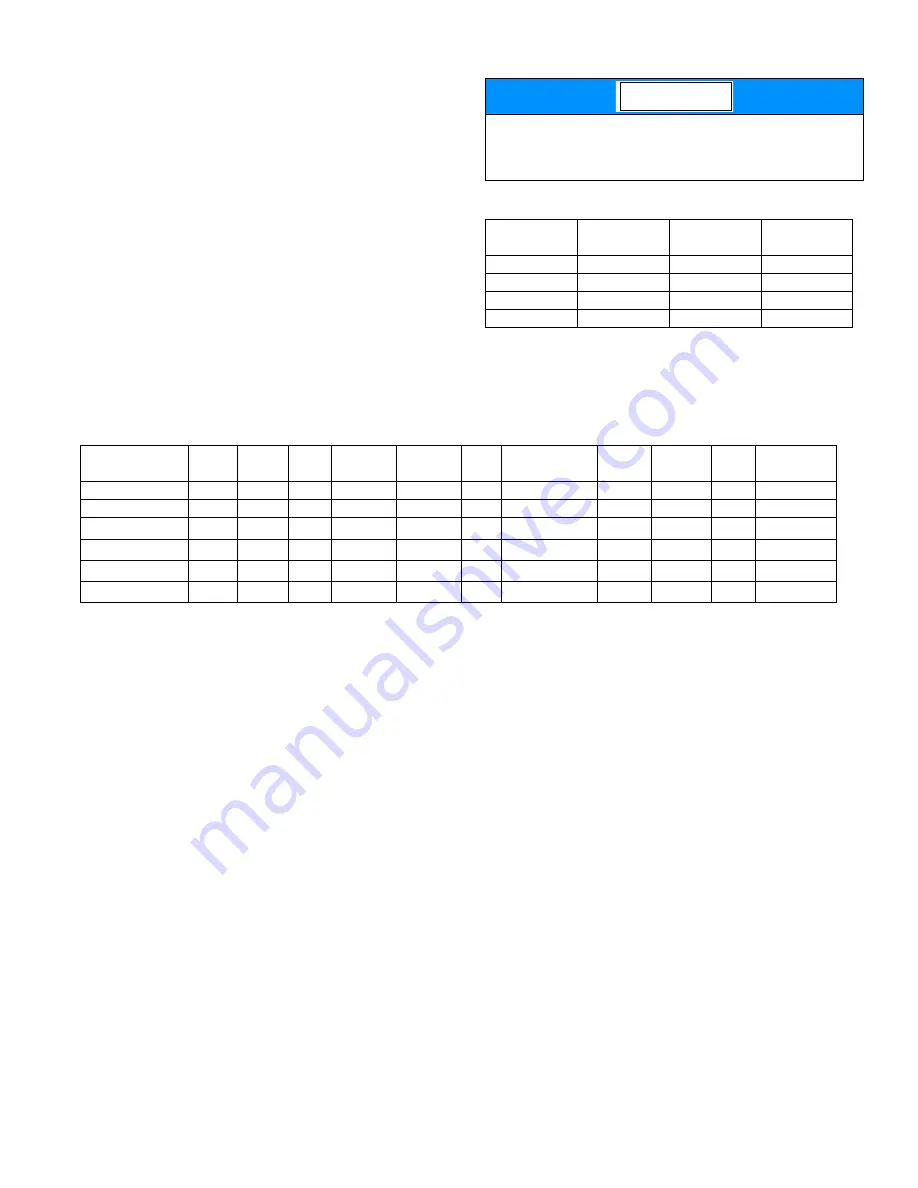

Recommended Filter Sizes

CFM

Cabinet

Size

Side

(in)

Bottom

(in)

1200

A

16 x 25

14 x 25

1200

B

16 x 25

16 x 25

1600

C

16 x 25

20 x 25

2000

C

(2) 16 x 25

20 x 25

NOTICE

Unit Clearances to Combustibles (All dimensions in inches, and all surfaces identified with the unit in an upflow configuration)

Application

Top

Front

Rear

Left

Side

Right

Side

Flue

Floor/

Bottom

Closet

Alcove

Attic

Line

Contact

Upflow

1

1

0

0

0

6

Combustible

Yes

Yes

Yes

No

Upflow B-Vent

1

1

0

0

0

1

Combustible

Yes

Yes

Yes

No

Downflow

1

1

0

0

0

6

1

1

1. Special floor base or air conditioning coil required for use on combustible floor.

Yes

Yes

Yes

No

Downflow B-Vent

1

1

0

0

0

1

1

1

Yes

Yes

Yes

No

Horizontal

1

1

0

0

0

6

Combustible

No

Yes

Yes

Yes

2

2. Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position) of the furnace jacket and build-

ing joists, studs or framing.

Horizontal B-Vent

1

1

0

0

0

1

Combustible

No

Yes

Yes

Yes

2