JOHNSON CONTROLS

78

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

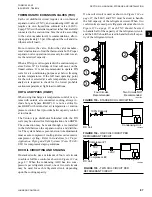

•

Use the actual operating conditions (coil pressure

vs. return pressure) to select a trap.

•

It is preferable to provide an individual trap for

each coil, but a single trap may be used for coils

operating in parallel with respect to the airflow.

Coils in series with respect to airflow must be sup

-

plied with individual traps.

•

Locate the trap at least 12 in. below the coil return

connection, and lower it when freeze protection is

required. Do not attempt to lift condensate modu-

lated steam supply.

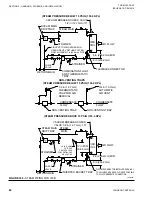

FIGURE 121 -

STEAM COIL PIPING ARRANGEMENTS

LD04887a

SUPPL

Y MAIN

DRIP TRAP

FOR END OR

LOW POINT

OF SUPPLY

MAIN

RETURN

MAIN

SUPPL

Y MAIN

SUPPL

Y

MAIN

SUPPL

Y MAIN

VENT TO

ATMOSPHERE

CLOSE TO

UNIT (NOT ON

VACUUM

SYSTEMS)

AIR FLOW

AIR FLOW

RETURN MAIN

RETURN MAIN

PITCHED IN CASING

STEAM COIL

STEAM COIL

PITCHED IN CASING

12" MIN.

12" MIN.

SINGLE COIL

VERTICAL AIR FLOW

12" MIN.

12" MIN.

12" MIN.

COILS IN PARALLEL AIR

FLOW MAY HAVE COMMON

SUPPLY AND SINGLE TRAP

(INDIVIDUAL COIL TRAP

PREFERRED)

COILS IN SERIES AIR FLOW

MUST HAVE INDIVIDUAL

TRAPS AND CONTROL

VALVES

RETURN MAIN

DIRT POCKET (FULL

SIZE OF COIL CONN.)

F & T TRAP

VACCUM

BREAKER

1/2" CHECK

VALVE

(OPTIONAL)

DIRT

(FULL SIZE

OF COIL

CONN.)

VACUUM

BRAKER

1/2" CHECK

VALVE

(OPTIONAL)

SYMBOLS FOR "SS" STEAM

COIL PIPING ARRANGEMENTS

GATE VALVE

STRAINER

CONTROL VALVE

(MODULATING OR

TWO POSITION)

CHECK VALVE

FLOAT AND

THERMOSTATIC

TRAP