JOHNSON CONTROLS

50

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

Installing Field Supplied MZ Damper

Actuators

When the actuators are field supplied for MZ dampers,

use the following information to select the correct size

actuator.

•

Required torque is 7 in-lb/sq. ft of damper area up

to 2500 feet per minute (FPM).

•

Damper blades are 6 in. wide and vary in height.

•

Calculate the torque by the number and size of

blades in each zone. There are hot deck blades di-

rectly connected to cold deck blades.

•

Determine the number of blades per zone by the

system cubic ft per minute (CFM), and static pres-

sure requirements for each zone by the engineer’s

construction documents.

• Cut the blade linkage (flat rods) connecting all

blades of each deck at the appropriate places to di-

vide the decks into correct size zones. These rods

are mounted externally on the assembly. Make

sure to cut out a section of the flat connecting rod,

which will prevent interference when the zones

modulate in opposite directions.

•

One damper shaft extension kit (P/N 026-33715-

vided for each zone per the factory order form.

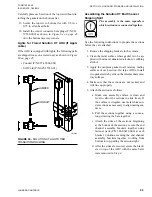

FIGURE 74 -

DAMPER SHAFT EXTENSION KIT

(P/N 026-33715-002)

LD116504

•

The contractor should supply the actuators and

mounting brackets. The part numbers are avail-

able upon request.

•

On the rear mount (discharge through end of the

AHU), always mount the actuators on the top of

the upper deck.

•

Do not allow the duct insulation to restrict the

damper blades or external linkage.

•

Direct coupled actuators are recommended.

•

Make duct connections at the zone dividers with-

out restricting the damper blade(s).

BACK DRAFT DAMPERS FOR DUAL FANS

AND FAN ARRAYS

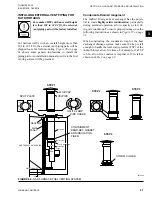

The counterbalance is locked into place for shipping

as shown in

. Before startup,

the counterbalance will have to be released. To do this,

loosen the set screws and slide the counterbalance off

the end of the shaft. Flip the counterbalance and slide

it back on the shaft. Rotate the counterbalance above

the damper as shown in

, and

then tighten the set screws. The counterbalance should

be free to rotate.

FIGURE 75 -

COUNTERBALANCE LOCKED INTO

PLACE FOR SHIPPING

LD17103

FIGURE 76 -

COUNTERBALANCE UNLOCKED FOR

START-UP

LD17198