Summary of Contents for Millennium YCAS0130EC

Page 5: ...YORK INTERNATIONAL 5 FORM 201 19 W1 304 This page intentionally left blank...

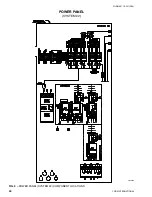

Page 25: ...YORK INTERNATIONAL 25 FORM 201 19 W1 304 LEGEND LD09241...

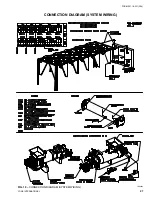

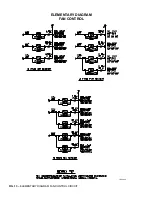

Page 26: ...YORK INTERNATIONAL 26 FORM 201 19 W1 304 LD03282 LD03283 2 ACE MOTOR PROTECTOR MODULE LD03284...

Page 31: ...YORK INTERNATIONAL 31 FORM 201 19 W1 304 NOTES...