TECHNICAL APPENDIX

Unit Capacity

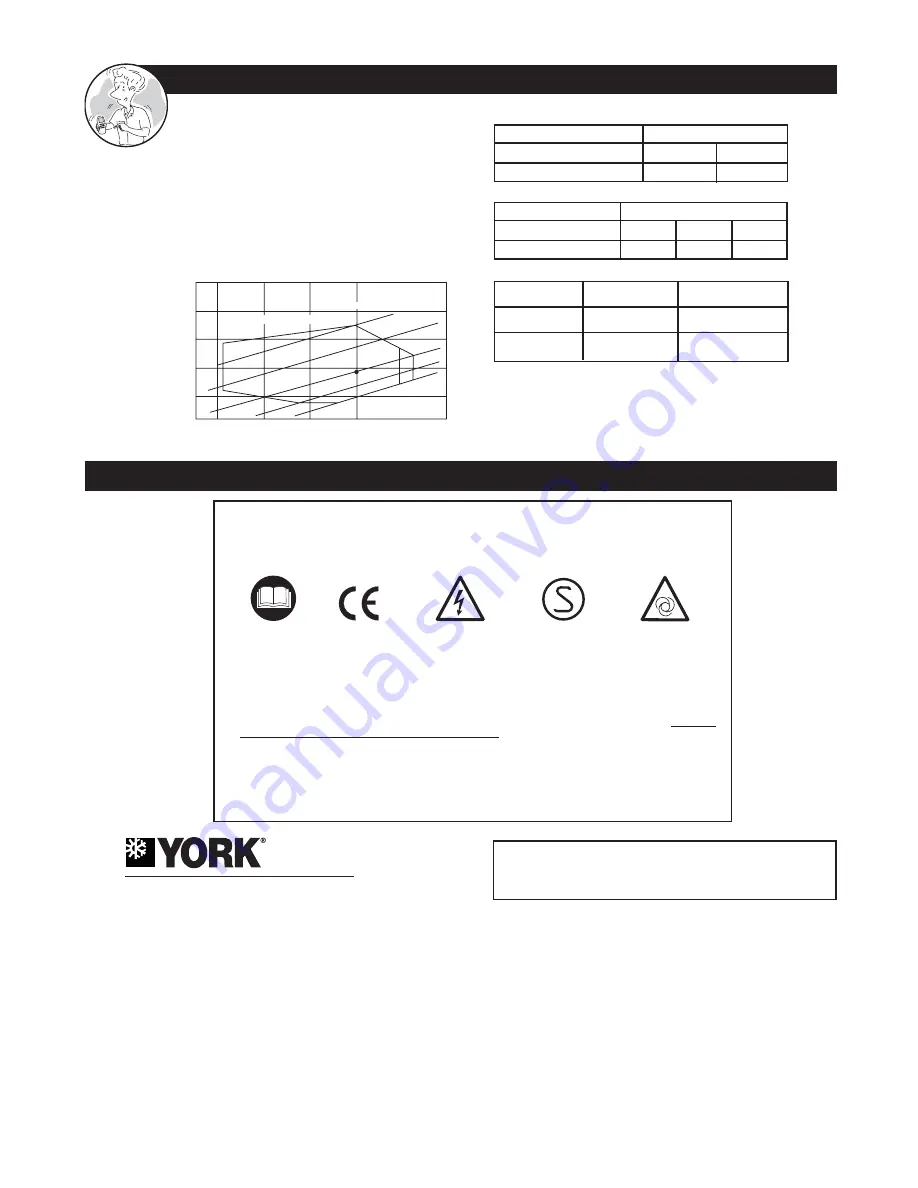

Total cooling capacity can be determined by using

correction factors C1, C2 and C3.

Given cooling capacity = Cooling capacity at

standard rating conditions x C1 x C2 x C3.

C1 = Capacity correction factor for temperature

C2 = Capacity correction for piping length

C3 = Capacity correction for indoor unit fan speed

Capacity correction factor for temperature

20

10

15

20

25

30

35

25

30

35

40

45

Air intake dry bulb temperature, outdoor unit (CDB)

Inlet air wet b

ulb temperatur

e

, indoor unit (CWB)

R.C.

120%

110%

100%

90%

85%

Capacity correction factor C1

Operating temperature range

DECLARATION OF CONFORMITY

Capacity correction factor for piping length (C2)

Piping length (m)

Correction factor C2

Indoor unit

10

0.98

5

1.00

Cooling mode

Heating mode

Maximum

Minimum

+ 19

º

C

(– 5 with low ambient kit)

– 8

º

C

+ 46

º

C

+ 28

º

C

(heat pump mode)

Fan speed

Correction factor C3

Indoor unit

High

1

Medium

0.90

Low

0.75

R.C.

= Standard rating conditions :

Indoor 27

°

C DB / 19.5

°

C WB

Outdoor 35

°

C DB / 24

°

C WB

Capacity correction factor for indoor fan speed (C3)

Operating temperature limits

DE - COMMISSIONING DISMANTLING & DISPOSAL

This product contains refrigerant under pressure, rotating parts, and electrical connections which may be a

danger and cause injury!

All work must only be carried out by competent persons using suitable protective clothing and safety precautions.

Read the Manual

Risk of electric shock

Unit is remotely

controlled and may

start without warning

1.

Isolate all sources of electrical supply to the unit including any control system supplies switched by the unit. Ensure

that all points of electrical and gas isolation are secured in the OFF position. The supply cables and gas pipework may

then be disconnected and removed. For points of connection refer to unit installation instructions.

2

. Remove all refrigerant from each system of the unit into a suitable container using a refrigerant reclaim or recovery unit.

This refrigerant may then be reused, if appropriate, or returned to the manufacturer for disposal.

Under No

circumstances should refrigerant be vented to atmosphere.

Where appropriate, drain the refrigerant oil from each

system into a suitable container and dispose of according to local laws and regulations governing disposal of oily

wastes.

3.

Packaged unit can generally be removed in one piece after disconnection as above. Any fixing down bolts should be

removed and then unit lifted from position using the points provided and equipment of adequate lifting capacity.

Reference MUST be made to the unit installation instructions for unit weight and correct methods of lifting. Note that

any residual or spilt refrigerant oil should be mopped up and disposed of as described above.

4.

After removal from position the unit parts may be disposed of according to local laws and regulations.

YORK

®

International Corporation

035T83169-001