6.

Making clamping jaw with of the line cassette

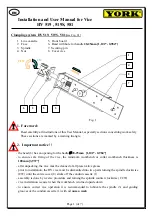

Dimensions minimum and optimum clamping jaw see page No.3, Fig.2b. Making clamping

jaw with of the line cassette is recommended made with finish allowance. First is make

mortising on front board into clamping jaw, follow drilling hole for spindle (

∅

30 for HV

519(S) and HV 581). See Fig.4a. Then is must insert eventually glue together to remainder

parts. Finally, is screw the line cassette . See Fig.4b.

7.

Completion mounting clamping jaw

The spindle complet with face insert into hole clamping jaw. Position the face is parallel to

jaw. The face screw-bolt.

Page 5 (of 7)

L

mm["]

ks

6-8

[0,24"-0,32"]

L=min

50

[

L=min

2"]

5

∅

4-6

[0,16"-0,24"

]

L

mm["]

ks

6-8

[0,24"-0,32"]

L=min

50

[

L=min

2"]

2

∅

4-6

[0,16"-0,24"

]

Fig.4a

Fig.5

∅

∅

S

mm["]

Fig.4b

∅

∅

S

mm["]

Mortising on front board (5)

into clamping jaw