Page 1 (of 7)

Installation and User Manual for Vice

HV 519 , 519S, 581

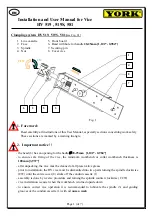

Clamping system HV 519, 519S, 581 (

see Fig. 1

) :

1. Line cassette

5. Front board

2. Face

6. Head with hole for handle

28-25mm [1,102“- 0,984“]

3. Spindle

7. Securing pin

4. Nut

8. Cover vice

1. Foreword:

Read carefully all instructions of this User Manual, especially sections concerning work safety.

These sections are marked by a warning triangle.

2. Important notice ! !

-

the head (6) has an opening for the hadle

∅

28-25mm [1,102“- 0,984“]

-

to ensure safe fixing of the vice, the minimum workbench or collar workbench thickness is

100mm [3,937“]

-

after unpacking, the vice must be cleaned of all preservative grease

-

prior to installation, the HV vice must be dismantled into two parts turning the spindle clockwise

(CW) until the entire cover (8) slides off the conduit cassette (1)

-

assembly is done by reverse procedure and turning the spindle counter clockwise (CCW)

-

vice installation is easier when the workbench is turned upside down

-

to ensure correct vice operation it is recommended to lubricate the spindle (3) and guiding

grooves of the conduit cassette (1) with oil

once a week

Fig. 1

2

4

5

3

1

6

7

CCW

CW

EN

8