4.4

External Water System

The external water hydraulic circuit must

ensure constant water flow to the evaporator

under all operating or adjustment conditions.

The plate heat exchangers fitted to YCAA-B/YCAA-H

units have multiple water passes with narrow water

channels that can be subject to premature fouling if the

design of the water system is not given adequate

consideration.

Water systems should be of the closed loop type, with

no tanks open to the atmosphere. The system should

have serviceable mesh strainers giving a filtration level

to at least 150 microns and anti-corrosion protection

using appropriate corrosion inhibitors, with

consideration to using purified water in geographic

areas where mains water has a high soluble solid

content.

York recommend that a water treatment specialist is

consulted to determine that the proposed water

composition will not affect the plate heat exchanger's

materials. Constant loss systems are not recommended

in any circumstance.

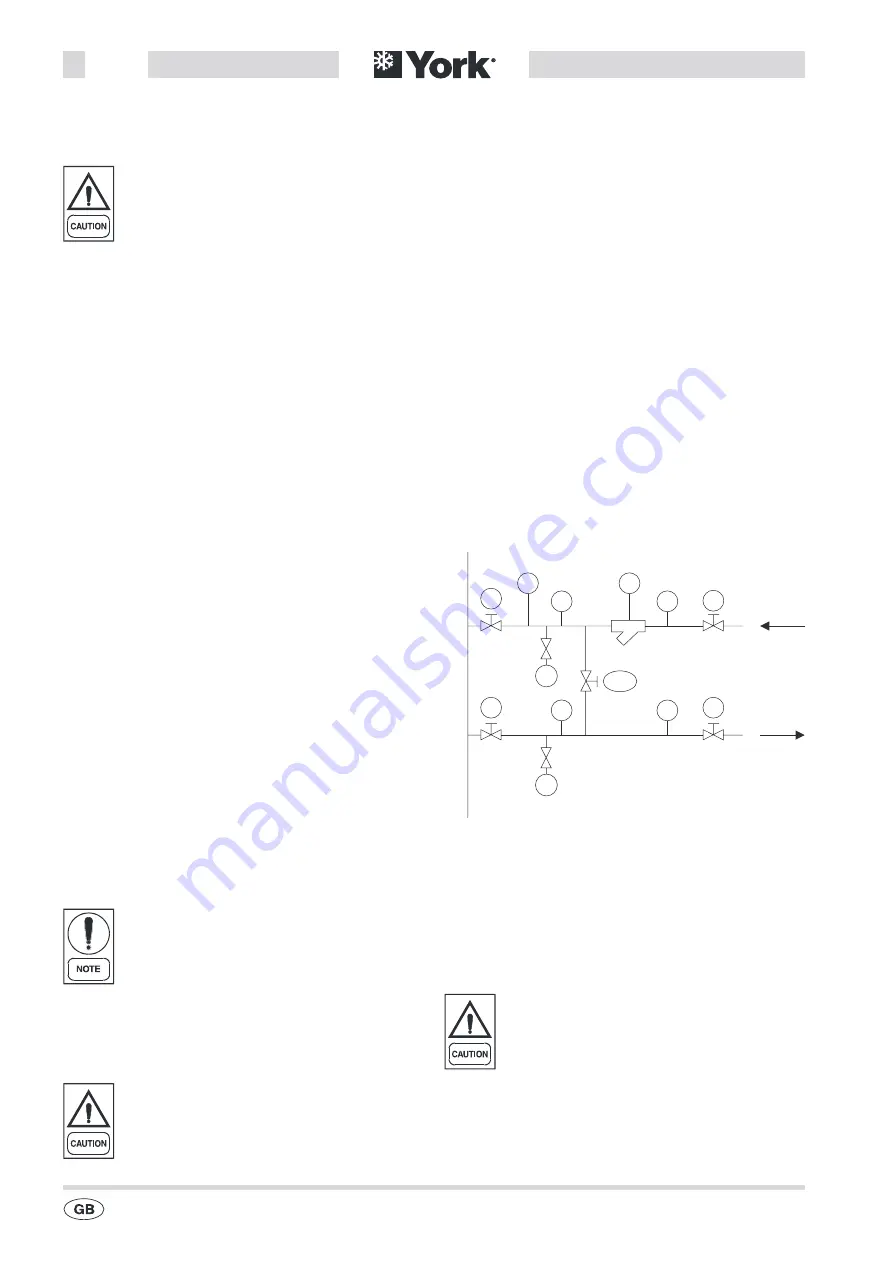

The external water system should consist of the

following:

n

A circulation pump providing sufficient output and

hydraulic head.

n

The primary system water content should be no

less than 10 litres per kW of cooling capacity. If the

total volume in primary system pipework and

evaporator is insufficient, an insulated reservoir

tank should be installed. This tank will ensure that

repetitive starts of the compressors are avoided.

n

A diaphragm-type expansion tank with safety valve

outlet which must be visible.

The tank should be sized to accommodate a

2% increase in total fluid volume in the system

(evaporator, lines, user circuits and reservoir

tank where provided). The expansion tank

does not need to be insulated, as water does

not normally circulate therein.

n

A flow switch to deactivate the unit when water is

not circulating.

The flow switch must be connected in series

with other external interlocks. The flow switch

should be installed on the pump delivery,

upstream of the unit.

A differential pressure switch is fitted as standard in the

unit. The pressure switch senses water pressure drop

across the evaporators and shuts down the unit when a

problem occurs.

In addition:

n

Install a 2” filter/strainer (150 mm mesh) on the inlet

side of the evaporator manifold.

n

Install shutoff valves on the evaporator manifold

inlet and outlet water lines.

n

Install a valved by-pass around the evaporator

manifold.

n

Install air vent valves at the highest points of the

lines.

n

Provide suitable drainage points (with plugs,

cocks, etc.) at the lowest points of the lines.

n

Insulate the pipework to prevent heat loss.

Key

I

Pressure

R

Drain tap

T

Temperature

F

Strainer

S

Gate valves

F1 Flow switch

S1 By-pass valve

Before filling the system, ensure that it is

free from foreign matter, sand, stones, rust

flakes, solder, slag or other materials which

could damage the evaporators.

It is advisable to by-pass the unit when flushing out the

lines.

(09/03)

4

-

2

035B09012-100 Rev. 4

S

S

S

E

va

po

ra

to

rM

an

ifo

ld

External Water System

T

T

I

I

S1

R

R

F1

F

S

Summary of Contents for YCAA B 120

Page 2: ......

Page 16: ...This Page Left Intentionally Blank 09 03 2 6 035B09012 100 Rev 4 ...

Page 28: ...This Page Left Intentionally Blank 09 03 4 10 035B09012 100 Rev 4 ...

Page 36: ...Page Left Intentionally Blank 09 03 6 6 035B09012 100 Rev 4 ...

Page 40: ...Page Left Intentionally Blank 09 03 7 4 035B09012 100 Rev 4 ...

Page 68: ...Notes 09 03 11 2 035B09012 100 Rev 4 ...

Page 69: ...Notes 09 03 035B09012 100 Rev 4 11 3 ...