3

In the upflow position, the heat ex-

changer support screw shown in the

picture may be removed. This may be

preferable if the furnace rear panel will

be inaccessible after installation. The

screw must be removed if the heat ex-

changer must be removed from the cabi-

net. Do not remove this screw if installing

furnace in a horizontal position.

HORIZONTAL INSTALLATION

P3HMX

furnaces models are assembled

and shipped ready for installation in the

up-flow position. The furnace may be

installed in either of the horizontal posi-

tions; warm air discharging left or warm

air-discharging right by following these

steps:

Heat Exchanger Support Screw

1. Rotate the furnace 90° to the de-

sired position.

2. Remove the three nuts fastening the

oil burner assembly to the furnace.

Rotate the oil burner assembly to be

in the normal upright position.

3. Re-align the oil burner assembly to

the combustion chamber (fire-pot),

and then secure into place with the

three nuts.

NON-SUSPENDED INSTALLATION

Maintain clearances to combustibles as

outlined in Table 1. Installation on a

combustible floor requires a clearance of

1 inch. This can be done by using a non-

combustible material such as one-inch

thick channel iron or similar material. The

furnace must be supported in such a way

as to not allow twisting or sagging of the

cabinet. Suggestion; as a measure to

prevent fuel oil from accumulating in

locations other than the fire pot, as could

be the case in the event of nozzle drip,

install the furnace with an approximate 2

degree slope from the oil burner casing

towards the fire pot. Use shims made of

noncombustible material.

SUSPENDED INSTALLATION

Refer to Figure 1. Maintain clearances to

combustibles as outlined in Table 1. The

furnace may be suspended by field fabri-

cating a cradle of angle iron and

threaded rod. Secure the furnace with 2

inch minimum slotted angle or equiva-

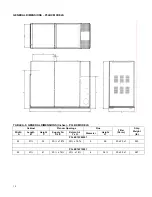

Table 1: Clearance to Combustibles

Furnace

P3LBX P3HMX

Location Upflow

Upflow

Horizontal

Top

1 in.

2 in.

2 in.

Bottom

0 in.

0 in.

1 in.

S/A Plenum

1 in.

1 in.

1 in.

Rear 0

in.

1

1 in.

1 in.

Sides 1

in.

2

1 in.

1 in.

Front

3 in.

9 in.

1

9

in.

1

4 in.

3

Flue Pipe

8 in.

4

9 in.

9 in.

Enclosure Closet

Closet

Alcove

1

24 inches is required for servicing.

2

18 inches is required on one side as service access to rear.

3

4 inches measured horizontally or below flue pipe.

4

8 inches measured vertically or above flue pipe.

Fig. 1:

Typical Sus-

pended Application

Summary of Contents for P3HMX12F08001

Page 16: ...16 APPENDIX A WIRING DIAGRAM ...