103904-UIM-B-0505

Unitary Products Group

5

INDOOR UNIT PREPARATION

Prepare Air Handler for installation as follows:

1.

Attach coil casing to blower section in a way appropriate to indoor

unit application. See appropriate “BLOWER / COIL ASSEMBLY”

instructions for G2FD Coils.

2.

Confirm the metering device.

NOTE: If a humidistat accessory is installed with the system, a thermal

expansion valve kit must be installed on the indoor side.

NOTE: Instructions for installing accessories are included with the

accessories.

3.

Attach Filter Rack Accessory if applicable. The filter rack is

designed for use with G2FD coil or blower section in a downflow

configuration.

4.

For upflow and horizontal applications, insert filter in the filter com-

partment below the coil.

BLOWER / COIL ASSEMBLY UPFLOW AND

HORIZONTAL INSTALLATIONS

NOTE: See coil instructions prior to assembly for drain pan installation

or baffle adjustment.

1.

Apply neoprene gasket to top of coil.

2.

Position blower casing over coil opening.

NOTE: Tie plate and screws are provided with all full-cased coils.

3.

Align the six holes provided and attach tie plate to back of casings

using screws provided.

4.

Remove blower access panel.

5.

Fasten duct flanges of coil to duct flanges of air handler with

screws. See Figure 6.

6.

Secure toe plate of blower to top panel of coil using 2 screws pro-

vided.

7.

See sections on electrical and blower speed connections.

8.

Re-position and replace access panel.

BLOWER / COIL ASSEMBLY DOWNFLOW

INSTALLATION

1.

Position blower casing over duct connection and secure such that

the supply air end of the blower is down.

2.

Apply neoprene gasket to return-air side of air handler.

3.

Place coil casing over blower return opening.

4.

Align the six holes provided and attach tie plate to back of casings

using screws provided.

NOTE: Tie plate and screws are included with all full cased coils.

5.

Remove blower access panel and coil filter door.

6.

Secure the two toe plates of the blower section and coil using pro-

vided holes and 2 screws.

7.

See sections on electrical and blower speed connections.

8.

Re-position and replace access panel and filter door.

ELECTRIC HEATERS & OPERATING CONTROLS

The low voltage transformer and the CFM board fan / heater control are

standard on all models. The air handlers are shipped pre-wired to oper-

ate as cooling only applications. To complete the installation for cooling

only, install a 6-pin jumper plug to the control board to bypass the

heater limit controls. This jumper plug is secured to the duct cover near

the 4-pin power plug harness. Failure to install the plug will cause the

blower to run continuously. See Figure 10.

Mark the unit nameplate with the appropriate heater selection on the

space provided or NONE to indicate cooling only. To operate these units

with electric heat, it is necessary to field install an electric heater kit

(2HK). See Electric Heater Accessory Installation instructions for proper

installation procedure. Prior to installing electric heat, it is necessary to

perform the following procedure:

1.

Remove the 4-pin power plug from the control board (See Figure

10).

NOTE: This pin must not be used when electric heaters are installed.

2.

Remove the four (4) screws from the duct cover and remove the

duct cover from the air handler.

Right-hand Airflow Application Only - Models with Circuit

Breakers

If unit is to be installed for right hand air flow, the circuit breakers in the

heat kit will need to be removed and rotated 180°, so the OFF position

will be down when the cabinet is positioned on the right side. This is an

NEC requirement. Do One Set Of Breakers At A Time - to make sure

wires are reconnected properly. Loosen terminal screws on the wires

and gently pull the wires back from the breaker. Remove screws

securing the breaker plate and rotate 180°, then secure the breaker

plate and reconnect the wires to the breaker. Proper torque for terminal

screws is 35 in/lbs.

LOW VOLTAGE CONTROL CONNECTIONS

The 24 volt power supply is provided by an internally wired low voltage

transformer which is standard on all models. However, if the unit is con-

nected to a 208 volt power supply the low voltage transformer must be

rewired to the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can exit the unit on the top right hand

corner or the right hand side panel (see Figure 4, item K).

Install the 7/8" plastic bushing supplied with the unit in the selected hole

and keep low voltage wiring as short as possible inside the control box.

The field wiring is to be connected at the screw terminals of the control

board (Refer to Figures 12, 13, 14, 15, 16, 17, 18, 19, and 20).

Equipment should never be operated without filters.

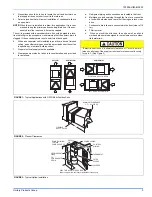

FIGURE 6: Tie Plate & Fastening Tabs

TIE PLATE

COIL

AIR HANDLER

COIL

TOP PLATE

AIR HANDLER

DOWNFLOW

APPLICATION

UPFLOW & HORIZONTAL

APPLICATIONS

Blowers installed in a downflow application with an electric heater

kit must include a non-combustible floor base if installing on a com-

bustible floor. See instructions for 1FB0617, 1FB0621 and

1FB0624.

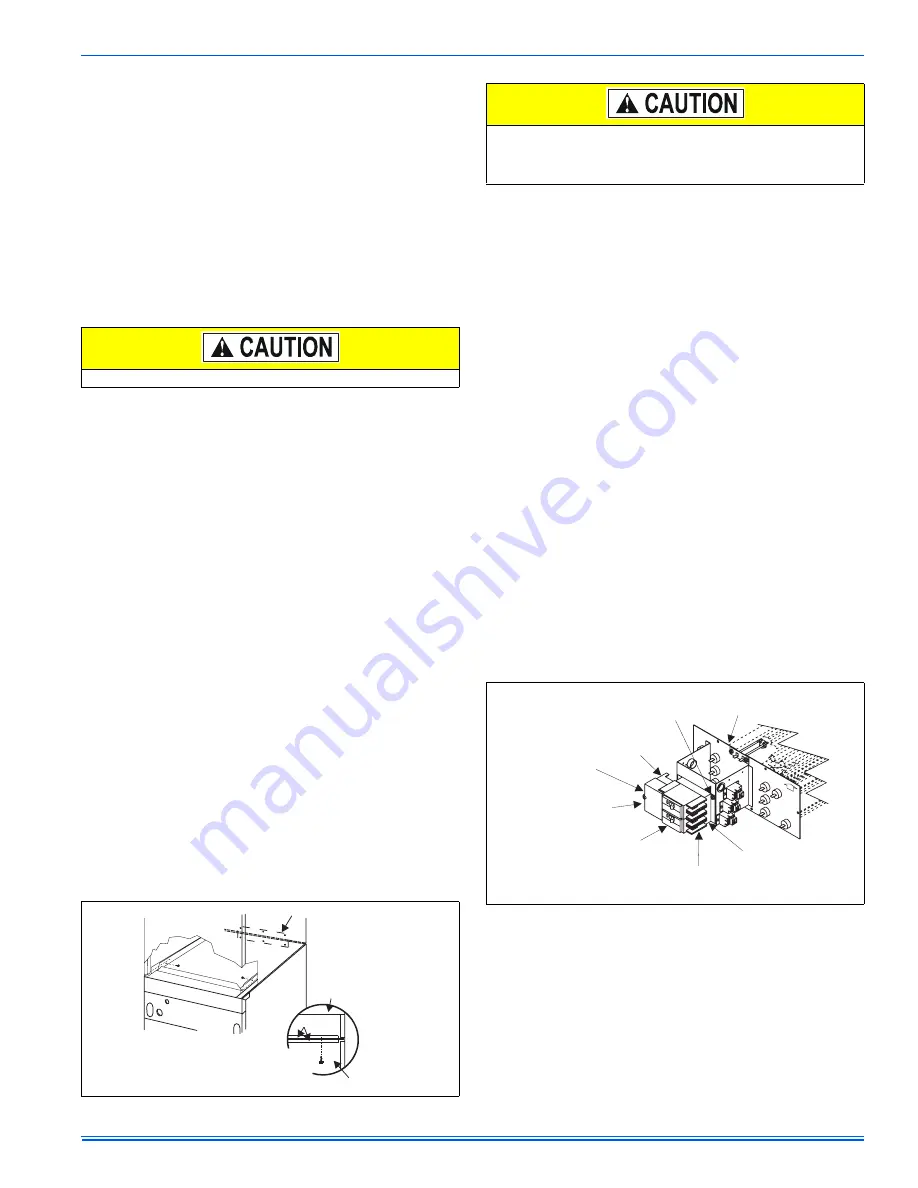

FIGURE 7: Electric Heaters in Horizontal Configuration

HEAT KIT

ASSEMBLY

REMOVE 3 SCREWS TO

REMOVE THE CIRCUIT

BREAKER BRACKET

FROM HEAT KIT

ASSEMBLY

JUMPER BAR

JUMPER BAR

COVER

FIELD SUPPLY WIRING

WILL BE ATTACHED TO

THIS SIDE OF THE

CIRCUIT BREAKER(S)

CIRCUIT BREAKER(S) -

THERE MAY BE ONE,

TWO OR THREE

CIRCUIT BREAKER

BRACKET

HEAT KIT WIRING WILL BE

ATTACHED TO THIS SIDE OF

THE CIRCUIT BREAKER(S)

AIR

FLOW