ESCO Equipment Supply Company

15270 Flight Path Drive, Brooksville Fl, 34604 Phone (352) 754-1117 Toll Free (800) 352-9852 Fax (352) 754-4508

www.esco.net

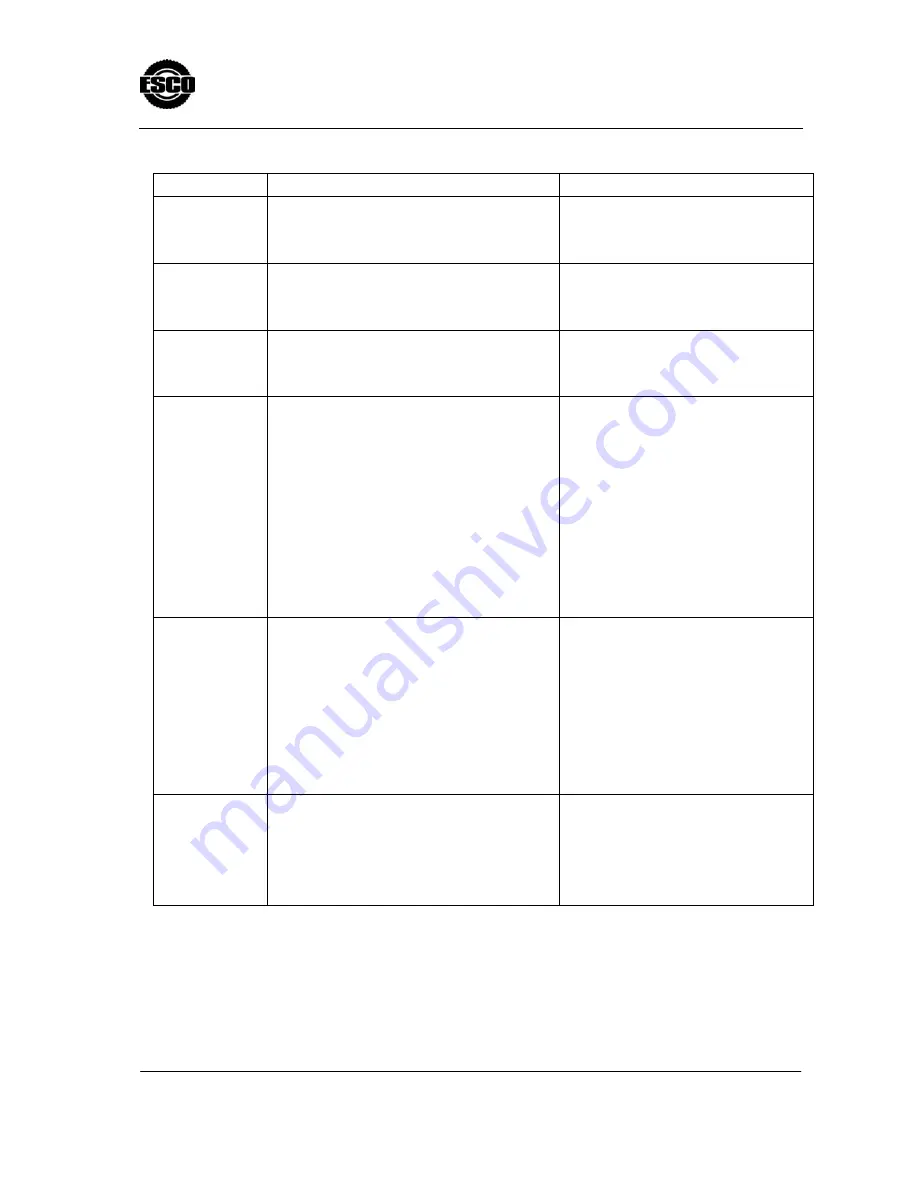

2) The Way of Troubleshooting.

Condition

Possible reason

Troubleshooting

Gas-leak under

the host

Connector or air pipe doesn’t connect in a

right way, or air pipe is broken.

Connect again or replace the air pipe or

connector after checking.

Gas-leak on oil

cylinder

Dust band or sealing and cylinder are broken

Check and replace the dust band or

sealing or spare parts.

A little bit of oil

leak

Oil runs into air pipe during the course of

transporting.

It is unnecessary to repair if it works in

good order

A great deal of

oil leak

1. The equipment started under the condition

of turnover.

2. Connector of oil inlet or sealing of oil

cylinder is broken.

3. Inside wall of cylinder is broken

1. Starting the equipment under the

condition of turnover is strictly

prohibited. If it is not in this

condition, check and make sure

whether there is enough oil in oil

tank or not, if not, it should add

more.

2. Check and replace spare parts.

3. Check and repair cylinder.

Booster pump

does not work

1.

One-way valve or spring is broken.

(see picture B)

2.

Booster piston or booster cylinder is

broken

3.

Air pressure is not enough, air pipe

removed or air inlet is plugged up.

1.

Check and replace the spare part.

2.

Check and repair, replace the spare

part if necessary.

3.

Check the air pressure whether is

within 90-130psi and the air way is

broken or not.

Booster pump

works in good

order but

cylinder does

not move up.

1.

Lack of oil.

2.

The steel ball of one-way valve is plugged

up.

3.

Oil Cylinder is broken.

1.

Fill it with hydraulic oil.

2.

Take the connector of oil inlet apart

and take out the one-way valve and

spring to clean it.

3.

Check and repair cylinder.