Maintenance and inspection

9

-

71

9.6

Setting the second home position (check point)

9.6.1

Purpose of position check operation

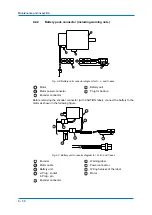

If the absolute number of rotations detected when the power is switched on does not match

the data stored by the absolute encoder the last time the power was switched off, an error

message is output.

There are two possible causes of this error message:

•

Error in the pulse generating system

•

The robot was moved after the power supply was turned OFF

If the alarm "OUTSIDE THE RANGE (ABSOLUTE DATA)" appears, automatic mode is not

possible. The home position must be checked.

If the "OUT OF RANGE (ABSO DA-

TA)" alarm occurs:

Compare second home position

(check point)* with current position

pulses.

Alarm reset

The alarm occurs again

Switch the servo power on

Correct the faulty axis, replace the

pulse generating system, set the

home position

Procedure after an alarm

* Position checking point

Position confirmation

Automatic mode possible

OK

NOK

1

6

2

7

3

8

4

9

5

10