Electrical Installation 2 - 12

Control Wiring

Control Circuit Wire Sizes

The auto mode speed reference (speed command) field wiring connection is made to E7 Drive terminals A1 or A2 (signal

positive), AC (signal common) and G (shield). Keep this lead length as short as possible to maintain signal quality. Insulated

twisted shielded pair wire (2 conductor # 18 ga, Belden 8760 or equivalent) is required. Do not run these wires in the same

conduit as other AC power or control wires. The shield must be connected on this end only, stub and isolate the other end. The

A2 signal employed is 4 to 20 mA with parameter H3-08 set for “2: 4 - 20 mA”. For 0 to 10 VDC, parameter H3-08 is set for

“0: 0 - 10 VDC” and the E7 control board DIP switch S1-2 must be in the OFF position. (See Fig 2.4).

For remote operation, keep the length of the control wiring to 50m or less. Separate the control wiring from high-power lines

(input power, motor leads or relay sequence circuits) to reduce noise induction from peripheral devices.

When setting speed commands (frequency references) from an external speed potentiometer (and not from the Digital Opera-

tor), use shielded twisted-pair wires and ground the shield to terminal E(G), as shown in Fig 2.3

.

Terminal numbers and wire

sizes are shown in Table 2.7.

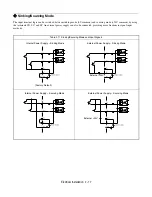

Fig 2.3 Analog Input Terminal Configuration

Table 2.7 Terminal Numbers and Wire Sizes (Same for all Drives)

Terminals

Terminal

Screws

Tightening

Torque

lb-in

(N•m)

Possible

Wire Sizes

AWG (mm

2

)

Recommended

Wire Size AWG

(mm

2

)

Wire Type

S1, S2, S3, S4, S5, S6, S7

SN, SC, SP, +V, A1, A2,

AC, MI, M2, M3, M4,

MA, MB, MC, FM, AC,

AM, R+, R-, S+, S-, IG

Phoenix

type

*3

4.2 to 5.3

(0.5 to 0.6)

Stranded

wire:

26 to 16

(0.14 to 1.5)

18

(0.75)

• Shielded, twisted-pair wire

*1

• Shielded, polyethylene-covered,

vinyl sheath cable

E(G)

M3.5

7.0 to 8.8

(0.8 to 1.0)

20 to 14

(0.5 to 2

*2

)

12

(1.25)

*1.

Use shielded twisted-pair cables to input an external speed command.

*2.

Yaskawa recommends using straight solderless terminals on digital inputs to simplify wiring and improve reliability.

*3.

Yaskawa recommends using a thin-slot screwdriver with a 3.5 mm blade width.

Signal

Terminal Connections

0-10Vdc

A1 to AC

4-20mA

or

0-10Vdc

A2 to AC

E(G )

+V +15V D C , 20m A

A 1 0-10V D C (20K )

A 2 H 3-08

4-20m A (250K )

[0 to +10V (20K )]

A C

E7

Ω

Ω

Ω

4 to 20m A

P

P

External

Frequency

R eference

2k

Ω

2k

(P=Pair)

External

Frequency

Reference

E (G)

2k

Ω

2k

P

P

4 to 20m A

+V +15VDC, 20mA

A1 0-10VDC (20k

Ω)

A2 H3-08

4-20m A (250K

Ω)

[0 to +10V (20K

Ω)]

AC