Electrical Installation 2 - 11

Cable Length between Drive and Motor

The E7 should be installed as close as possible to the motor to minimize the length of load side power cable needed between

the Drive and the motor.

If the cable between the Drive and the motor is long, the high-frequency leakage current will increase, causing the Drive

output current to increase as well. This may affect peripheral devices. To prevent this, reduce the cable length whenever

possible, or if necessary, adjust the carrier frequency (set in C6-02) as shown in Table 2.6.

The line side power cables, load side power cables and the control wiring should all be run in a separate conduit. Careful atten-

tion to this recommended design practice will avoid many potential motor and Drive related problems.

(See the limitations on carrier frequency, based on Drive capacity and model number in Appendix B).

Ground Wiring

Observe the following precautions when connecting the ground wire:

1.

208-240Vac Drives should have a ground connection with resistance of less than 100

Ω

.

2.

480Vac Drives should have a ground connection with resistance of less than 10

Ω

.

3.

Do not share the ground wire with other devices, such as motors or large-current electrical equipment.

4.

Always use a ground wire that complies with technical standards on electrical equipment and minimize the length of the

ground wire. Leakage current flows through the Drive. Therefore, if the distance between the ground rod and the ground

terminal is too long, potential on the ground terminal of the Drive will become unstable.

5.

When using more than one Drive, be careful not to loop the ground wire. See Fig 2.4.

Fig 2.2 Ground Wiring Examples

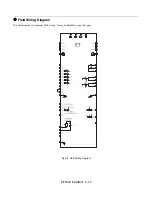

Control Circuit Ground Terminals

The removable Drive control terminal card provides two ground terminals (marked TB3 and TB4) to accept the control wire

shield connection. The control wire shield should be connected on this end only, the opposite end should be isolated with

electrical tape.

Table 2.6 Motor Cable Length vs. Carrier Frequency (C6-02)

Motor Cable Length

164 ft. (50m) maximum

328 ft. (100m) maximum

More than 328 ft.(100m)

Carrier Frequency

15kHz maximum

10kHz maximum

5kHz maximum

IMPORTANT

Grounding of the E7 enclosure and motor is required for proper system operation.

NO

OK

OK

NOT OK