NOTICE

These notices describe a situation

which, if not avoided, can cause damage

to the Sail-Drive, personal property and /

or the environment or cause equipment

to operate improperly.

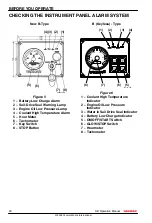

It is important to perform daily checks as

listed in this Operation Manual.

Periodic maintenance prevents unexpected

downtime, reduces the number of accidents

due to poor Sail-Drive performance and can

help extend the life of the Sail-Drive and

engine.

ALWAYS be environmentally

responsible.

Follow the guidelines of the

EPA or other governmental

agencies for the proper

disposal of hazardous materials such as

lubrication oil, diesel fuel and engine

coolant. Consult the local authorities or

reclamation facility.

NEVER dispose of hazardous materials by

dumping them into a sewer, on the ground

or into ground water or waterways.

NEVER attempt to modify the Sail-Drive’s

design or safety features.

• NEVER release or modify the limiting

devices such as the engine speed limit,

fuel injection limit, etc.

• Modification will impair the safety and

performance of the product and shorten

product life.

• Modifications to the design, safety or

limiting features will void the warranty.

If the Sail-Drive oil temperature is too high,

stop engine immediately and check the Sail-

Drive oil level and check the oil cooler for

proper coolant and water flow.

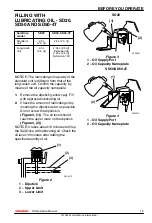

The anode of the Sail-Drive is only

calculated for the Sail-Drive. Changing the

material of the propeller may require

additional anodes to be installed on the sail-

drive.

Failure to use the correct anode material

may result in inadequate protection and

excessive corrosion of underwater drive

system components. Use only zinc or

aluminum anodes in brackish and saltwater

applications. In freshwater applications, use

aluminum or magnesium anodes for best

results. NEVER use magnesium anodes in

brackish or salt water, as they will

deteriorate rapidly, which will lead to severe

damage to the drive system.

SAFETY

SD Operation Manual

7

© 2009 Yanmar Marine International