EF494T OM

15

AFTER SALES SERVICE AND WARRANTY

After sales service

If your tractor is not working normally, refer to the

troubleshooting section in this manual. You can also

consult with your service representative.

Information needed when asking for service:

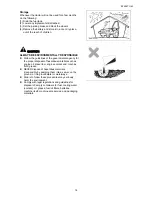

Model name and serial number (A) of your tractor.

Engine type number (B)

Operating conditions. What type of work was being

performed when the problem occurred?

How long have you used your tractor? (total hours of

operation)

Any other information about the problem that has

occurred.

Availability of spare parts

Maintenance parts and spare parts will be available for

10 years after the production of this tractor series has

been discontinued. However, special parts will be

available subject to consultation. Yanmar may be able to

supply a particular part after the normal supply period.

(A) Tractor serial number

(B) Engine type number

(A)

(B)

PURPOSE OF THIS MACHINE

This machine is designed to be operated with a various

implement for particular tasks and for pulling a trailer in

a variety of agricultural operations. Other use or

modification is prohibited.

Orientation and Position Marks

A right-hand and Left-hand side of the machine is

determined by facing in the direction of the machine

forward travel.