PERIODIC MAINTENANCE

90

TNV Operation Manual

7. Wash the inside of the cup.

8. Check the condition of the O-ring

. Replace in necessary.

9. Install the cup to the mounting flange and turn

the retaining ring

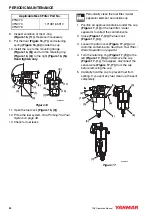

(Figure 14, (1))

to the right

.

Hand tighten only.

10. Open the fuel cock of the fuel filter / water

separator.

Figure 14

11. Prime the fuel system.

See Priming The Fuel

12. Check for fuel leaks.

Replace the fuel filter at specified

intervals to prevent contaminants from

adversely affecting the diesel fuel flow.

1. Stop the engine and allow it to cool.

2. Close the fuel cock of the fuel filter / water

separator.

3. Remove the fuel filter using a filter wrench to

turn it to the left

(Figure 15, (1))

. When

removing the fuel filter, carefully hold it to

prevent the fuel from spilling. Wipe up all

spilled fuel.

Figure 15

4. Clean the filter mounting surface and apply a

small amount of diesel fuel to the gasket of

the new fuel filter.

5. Install the new fuel filter. Hand tighten it to the

right

(Figure 15, (2))

until it comes in contact

with the mounting surface. Use a filter wrench

to tighten it one additional turn.

6. Open the fuel cock of the fuel filter / water

separator.

7. Prime the fuel system.

8. Check for fuel leaks.

Applicable Fuel Filter Part No.

2TNV70

3TNV70

3TNV76

119810-55650

(1)

(4)

(3)

(2)

(5)

000058

9

A

(6)

Applicable Fuel Filter Part No.

3TNV82A, 3TNV84,

3TNV84T, 3TNV88,

4TNV84, 4TNV84T,

4TNV88, 4TNV94L,

4TNV98

119802-55800

4TNV98T, 4TNV106,

4TNV106T

123907-55800

0000072A

(2)

(1)

Summary of Contents for 2TNV70

Page 1: ......

Page 2: ......

Page 32: ...SAFETY 14 TNV Operation Manual ...

Page 116: ...PERIODIC MAINTENANCE 98 TNV Operation Manual ...

Page 140: ...SPECIFICATIONS 122 TNV Operation Manual ...

Page 141: ......

Page 142: ......