The FDC-4000 controller is programmed by using three keys on the front

panel. The available key functions are listed in following table. Note: Only use

the tip of your finger to depress the keys. Using a rigid object such as a pen,

screwdriver or even your finger-nail may permanently damage the keypad.

TOUCH KEYS

FUNCTION

DESCRIPTION

Up Key

Press and release to increase the control set-point (while in normal control

mode) or to change lower display program parameter (while in User Menu or

Factory Mode). Press and hold to accelerate increment speed.

Down Key

Press and release to decrease the control set-point (while in normal control

mode) or to change lower display program parameter (while in User Menu or

Factory Mode). Press and hold to accelerate decrement speed.

Pressing

key while in

normal control

mode

Scroll Key

Press and hold for at least 2 seconds and release (while in normal control

mode) to access operator level parameters. Press and release to cycle

through all user parameters. Press and hold for 2 seconds and release to

silence audible alarm under normal power or on battery power. While unit is in

an alarm condition, the external alarm relay contacts will remain energized

until the alarm condition no longer exists. Press and hold to display chamber

temperature while the controller is on battery power. Chamber temperature will

be displayed until key is released. Alarm contact will remain energized while

operating on battery power.

Press both keys

simultaneously

Current Power

Reading

Displays current AC power (i.e. 110VAC) as long as keys are pressed. If

power is 110VAC or 220VAC, unit will display 110. Mode is only active during

normal control mode (when top display = PV, Lower display = SP). N/A on

battery power.

Press both keys

simultaneously

Alarm Test

Energize audible alarm and alarm relay output as long as keys are pressed.

Mode is only active during normal control mode (when top display = PV,

Lower display = SP). N/A on battery power.

Note: When the controller is displaying temperature in normal control mode,

press/release or press/hold the up/down keys to change the set-point value.

This set-point mode does not apply to power off modes.

9

CONTROL KEYS & DISPLAYS

CONTROL PROGRAMMING

TEMP

SET

-888

-888

Summary of Contents for ULF001C

Page 15: ...13 WIRING DIAGRAM...

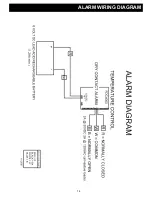

Page 16: ...14 ALARM WIRING DIAGRAM...

Page 17: ...15 REFRIGERATION FLOW CHART...