4-43

CRANKCASE AND CRANKSHAFT

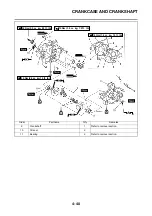

• Apply molybdenum disulfide grease

to the surface "a" where the crank-

shaft and bearing come in contact.

• Use two plain washers (Yamaha

genuine: 90201-243K3) "5" or the

ones of a size as shown one on the

other. (Except for USA and CDN)

• Install so that the plain washers do

not deviate from the crankshaft cen-

ter. (Except for USA and CDN)

• When installing the crankcase, the

connecting rod should be posi-

tioned at TDC (top dead center).

• Install while checking that the dowel

pin is in place.

A. For USA and CDN

B. Except for USA and CDN

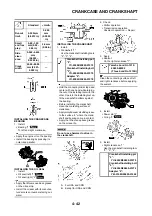

6. Install:

• Clamp "1"

• Bolt (crankcase) "2"

Tighten the crankcase tightening

bolts in stage, using a crisscross pat-

tern.

7. Install:

• Holder "1"

• Bolt (holder) "2"

8. Install:

• Segment "1"

• Bolt (segment) "2"

• When installing the segment onto

the shift cam "3", align the punch

mark "a" with the dowel pin "b".

• Turn the segment clockwise until it

stops and tighten the bolt.

If the segment gets an impact, the

stopper lever may be damaged.

Take care not to give an impact to

it when tightening the bolt.

9. Remove:

• Sealant

Forced out on the cylinder mating

surface.

10. Apply:

• Engine oil

To the crank pin, bearing, oil de-

livery hole and connecting rod big

end washer.

11. Check:

• Crankshaft and transmission op-

eration.

Unsmooth operation

→

Repair.

If the crankshaft will not turn smooth-

ly, make an adjustment by gently tap-

ping its right end with a soft hammer.

Bolt (crankcase):

14 Nm (1.4 m•kg, 10

ft•lb)

Bolt (holder):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (segment):

30 Nm (3.0 m•kg, 22

ft•lb)

Summary of Contents for YZ125 2016

Page 4: ......

Page 12: ...1 2 LOCATION OF IMPORTANT LABELS EUROPE...

Page 13: ...1 3 LOCATION OF IMPORTANT LABELS AUS NZ ZA...

Page 61: ...3 18 CHASSIS...

Page 165: ......

Page 166: ...PRINTED IN JAPAN E PRINTED ON RECYCLED PAPER...