– 47 –

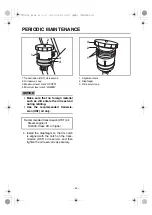

1. Spark plug cap

4. Remove the spark plug using a plug

wrench.

5. Check the spark plug for any signs of

burns.

Burn marks on spark plugs are usually

medium-to-light tan. If there are any

black or white burn marks, consult your

Yamaha dealer.

6. Remove deposits (carbon) from the

spark plug electrode using a plug

cleaner or a wire brush.

7. Check the spark plug gap.

1. Spark plug gap

2. Spark plug number

3. Insulator

8. Install the spark plug.

TIP

If a torque wrench is not available when

installing a spark plug, a good estimate of

the correct torque is 1/4–1/2 turn past finger

tight. However, the spark plug should be

tightened to the specified torque as soon as

possible.

1. Fully tighten the spark plug using your fingers.

2. 1/4–1/2 turn

Spark plug:

NGK BPR4ES

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

1

Tightening torque:

18 Nm (1.8 m·kgf, 13 ft·lbf)

1

2

3

1

2

PERIODIC MAINTENANCE

7VY-9-70_E0.fm 47 ページ 2010年4月30日 金曜日 午前9時35分