ELEC

Electrical systems

–

+

8-19

6C13G11

4.

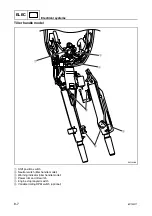

Check the armature for continuity.

Replace if out of specifications.

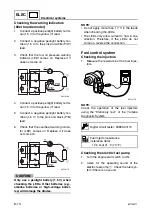

Checking the brushes

1.

Measure the brush length. Replace the

brush assembly if below specification.

2.

Check the brush holder assembly for

continuity. Replace if out of specification.

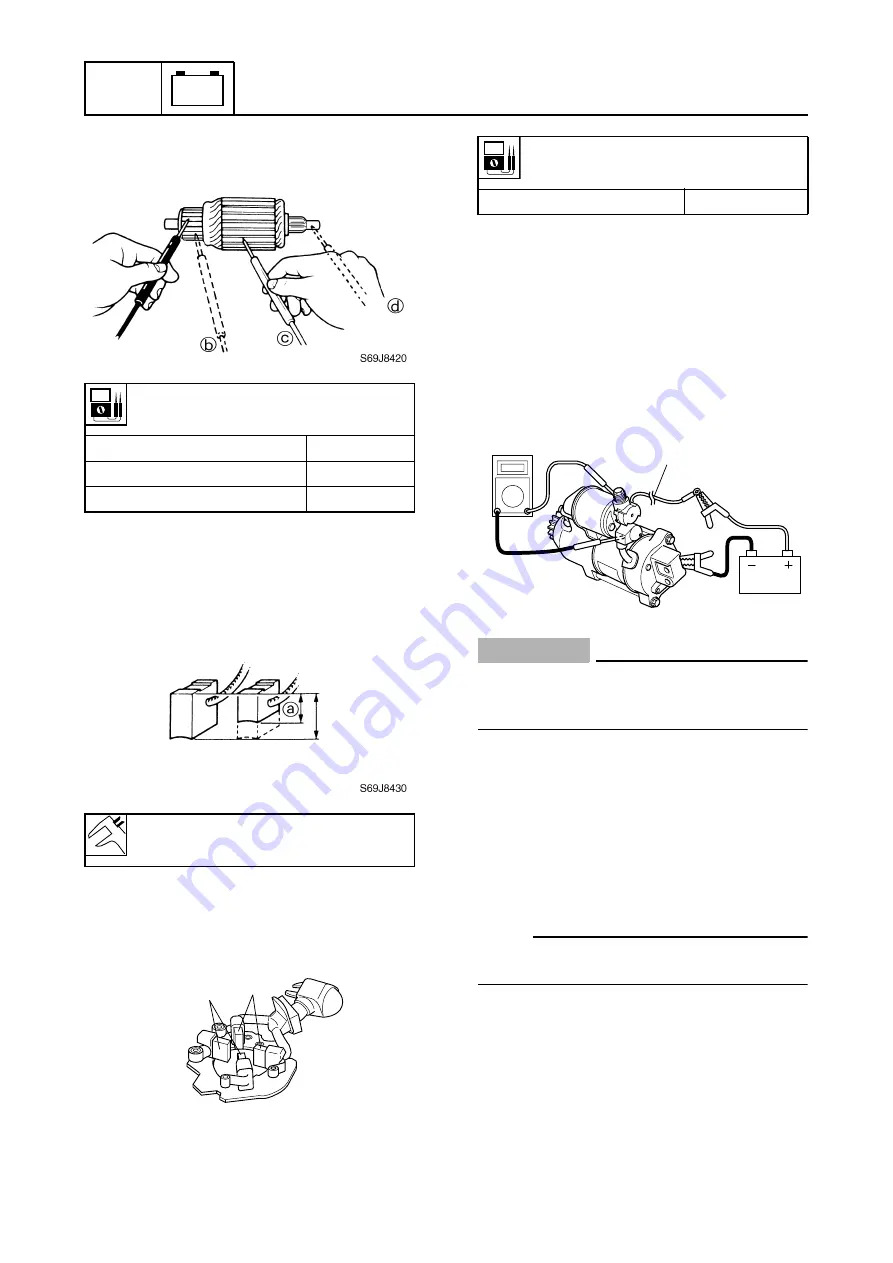

Checking the magnet switch

1.

Connect the tester leads between the

magnet switch terminals as shown.

2.

Connect the positive battery lead to the

brown (Br) lead.

3.

Connect the negative battery lead to the

starter motor body.

CAUTION:

Do not connect the battery for more than

one second, otherwise the magnet switch

can be damaged.

4.

Check that there is continuity between

the magnet switch terminals. Replace if

there is no continuity.

5.

Check that there is no continuity after the

negative battery terminal is removed.

Replace if there is continuity.

NOTE:

The starter motor pinion should be pushed

out while the magnet switch is on.

Checking the starter motor operation

1.

Check the operation of the starter motor

after installing it onto the power unit.

Armature continuity

Commutator segments

b

Continuity

Segment – Armature core

c

No

continuity

Segment – Armature shaft

d

No

continuity

Brush length wear limit

a

:

9.5 mm (0.37 in)

S69J8440

1

2

Brush continuity

Brush

1

– Brush

2

No

continuity

S6D88130

Br

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...