– 49 –

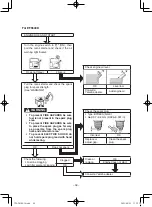

Fuse Replacement (For EF5500DE)

WARNING

Be sure to use specified fuse. A wrong fuse will

cause electrical system damage and A FIRE

HAZARD.

NOTICE

Be sure the engine switch is turned to “

5

” (STOP)

to prevent accidental short circuiting.

1. Remove the control panel screws and then

remove the control panel.

1

Control panel screw

2. Replace the blown fuse with one of proper amper-

age.

Specified fuse: 20 A

TIP

If the fuse immediately blows again, consult a Yamaha

dealer.

1

1

7P5-F8199-14.indd 49

2021/06/23 11:22:19