4

Fig. 5

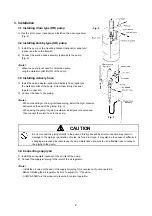

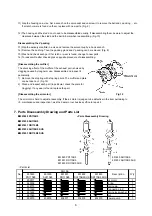

5. Maintenance and Inspection

5.1 Troubleshooting and Corrective Measures

Symptom

Contents of inspection

Corrective measure

The pump fails to start.

- Check if the air regulator is normally operated.

- Check if the valve in the course of the pipe is not

closed.

(Remove the delivery hose at the pump-side outlet and

operate the pump.)

If the pump is operated, the delivery hose, pipe, or

outlet valve (gun) is clogged, or the operating

pressure is low.

If the pump is not operated, the pump is defective.

(Separate the lower pump and operate the pump with

only the air motor.)

If the pump is operated, the lower pump is defective.

If the pump is not operated, the air motor is defective.

Pressure check.

(0.15 to 0.7MPa)

Inspection

Repair service for

the lower pump

Repair service

The pump fails to stop.

- Check if the pump cannot be stopped when the

material outlet side remains open.

- If the outlet side is closed, check if any leak occurs at

the pipe, delivery hose, or each connecting portion.

- Check if the air bleed valve or bleeder valve remains

open.

- Check if there is no material.

Inspection

Replenishment

The pump is operated

but does not feed the

material by pressure.

- Loosen the air bleed valve to bleed the air staying

under the inductor plate and tighten the valve again.

- If the pump cannot be operated, open the bleeder

valve. When the material comes out, tighten the valve

again.

If the material is not fed, disassemble the check valve

and clean and check the ball seat surface and spring.

- The pump cannot be operated yet, the pump is

defective.

Inspection

Inspection

Disassembly and

inspection

Repair request for

the lower pump

The pump is operated

but the pressure and

flow rate are insufficient.

- Check if the supply air pressure is insufficient.

- Check if the packing of the air valve is not worn away.

Pressure check

Repair request for

the lower pump

5.2 Maintenance and Inspection

[Oiling]

For lubrication of the pump, perform oiling with a lubricant once every 10 days.

Apply the lubricant as follows.

1) Remove the air regulator.

2) As shown in the Fig. 5 at right, inject drops of lubricant (approximately 0.5mL)

into the oil cup. Use turbine oil first class ISO (VG-32) as the lubricant.

[Inspection]

The packing and parts around slide portion of the pump are worn away. Check

and replace them once a year.

[Daily check]

Before starting pump operation, retighten the bolts or connection parts of the pump. (Fig. 6)

Fig. 6

Summary of Contents for 110 Series

Page 17: ...MEMO ...