3

4. Operating Method

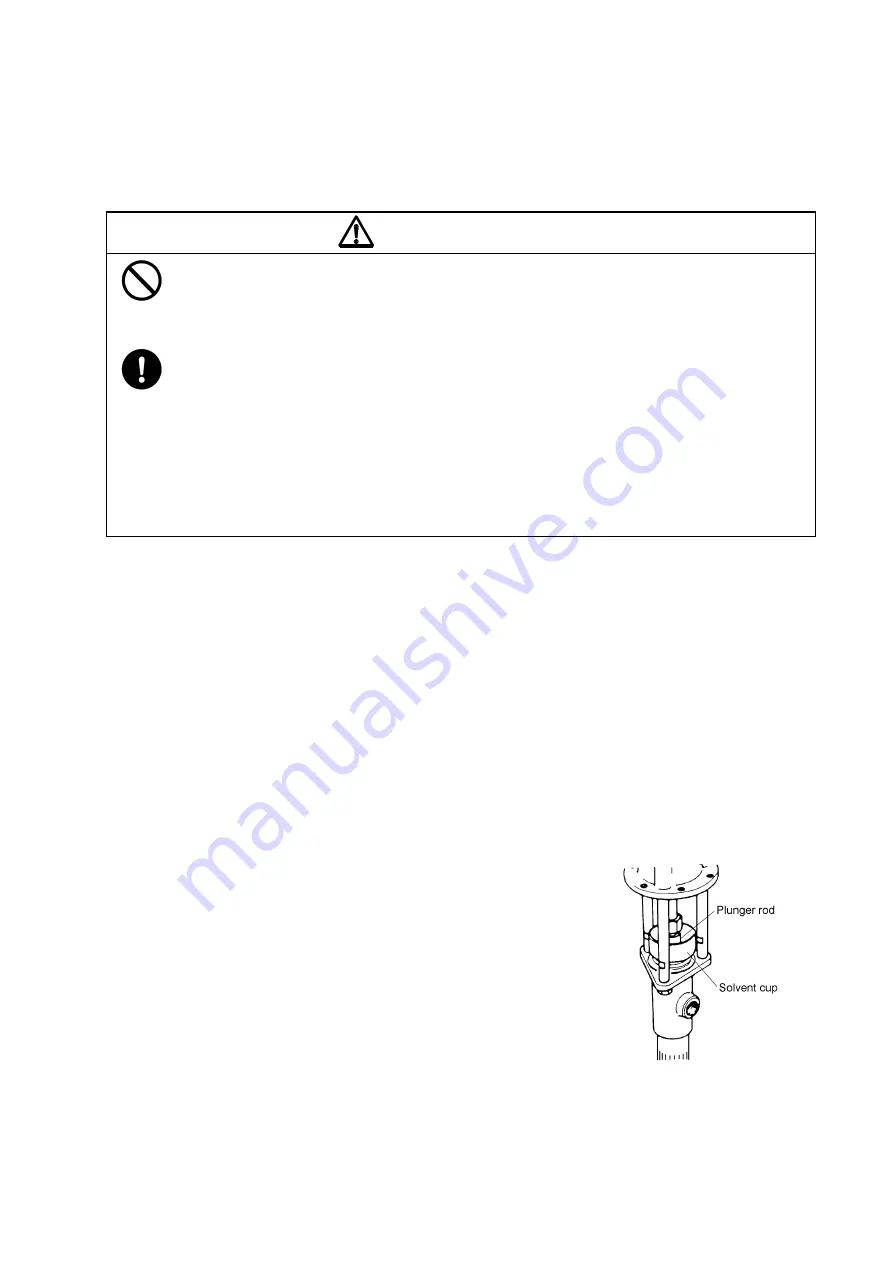

The pump is equipped with the solvent cup. To protect the plunger rod and packing from damage caused by dried and

stiffed pumping material, pour solvent or suitable lubricant to 2/3 level of the cup. (Fig. 4)

CAUTION

- Do not bring a face close to the exhaust port of the operating pump in any case. Because of the high

exhaust pressure, water may be frozen and it could cause injury.

- Do not put hands in the 3 studs that connect the air motor to the lower pump. Hands may be caught by

the plunger in reciprocating motion. It may result in an injury.

- The maximum operating air pressure of this machine is 0.7MPa. Using the machine exceeding 0.7MPa

may result in a bodily injury or property damage. Do not operate the machine over 0.7MPa. If the air

line is 0.7MPa, reduce the air line to 0.7MPa or less by using the air regulator.

- Regarding a secondary accident such as hose damage that may be caused by not shutting off the air

supplied to the hose or floor contamination due to a leak from the valve or gun after completion of the

work or at night, the responsibility rests with the user side.

- When the pump causes a malfunction or stop operation, do not disassemble the pump thoughtlessly.

Make sure to disassemble only necessary parts, referring to <5.1 Troubleshooting and Corrective

Measures> and judging the situation properly.

1) Turn the knob of the air regulator clockwise to supply air into the pump. When the supply air pressure reaches

0.15 to 0.2MPa, the pump starts to operate. The pointer of the pressure gauge indicates the supply air pressure.

2) When air is supplied, the pump is operated for a while to fill the hose, pipe, and gun with oil, and then stopped

automatically. If the pump is continuously operated without stop, leak may have occurred in any connecting portion

of the hose, pipe, or gun. Stop the air supply and make a check.

3) Operating the gun lever at the end of the delivery hose discharges oil. When the lever is pulled, the valve is

opened and the pump is automatically operated to discharge oil. When the lever is reset, the valve is closed to

stop the oil discharge and the pump is also stopped.

4) Adjust the supply air pressure according to the application. Usually, the operating pressure should be 0.3 to

0.5MPa. In particular, when the pump is used for feeding oil, the discharge volume differs depending on the piping

length and oil viscosity. Adjust the supply air pressure to your desired level.

5) After completion of the work, be sure to stop the supply air to the pump.

<Note>

- After completion of the work or when the pump is not operated

for a long time, keep the plunger rod bottom position and soaked

into the solvent cup to prevent damage on the packing by dried

material that stuck on the plunger rod. (Fig. 4)

- If the oil in the drum has run out, the pump will be operated at a higher

speed without oil. This may have an adverse effect on life of pump.

Stop the pump operation at once and replace the drum to the new one.

Fig. 4

Summary of Contents for 110 Series

Page 17: ...MEMO ...