4

Installation

03.2018

41

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

4.9

Electrical equipment

DANGER

Electric shock hazard

➢

Make sure an electrical qualified person performs the work.

➢

Observe the relevant safety and accident prevention regulations.

The electrical equipment of the hoist was designed, manufactured and tested in

accordance with standard EN 60204-32. It comprises all electrical equipment of the hoist:

Electrical equipment was installed per NFPA 70 or other National, State, and Local

regulations.

•

Energy supply (main isolator, conductor lines…)

•

Energy distribution (transformers, crane

disconnect switch, special circuits…)

•

Operator interface and control devices mounted on the hoist (control pendant, radio

transmitter, devices for emergency stop, limit switches…)

•

Hoist control (electronic control devices, safety devices, radio receiver…)

•

Drive, motor controls (power contactors, inverters…)

•

Main drives (motors, brakes…)

•

Auxiliary drives, sensors, load suspension equipment, actuators…)

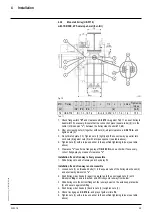

4.9.1

Supply cables

Electrical service can be either power by cable or guarded system having sliding show

contacts or wheel type collectors.

1.

See section 11.3 for minimum cross-section and max. length of supply cable.

2.

Select cables, leads and conductor lines to match the existing operating conditions

(e.g. voltage, current, protection against electric shock, amassment of cables and

leads) and for external influences (e.g. ambient temperature, presence of water or

corrosive materials, mechanical stress).

4.9.2

Terminals

1.

Check that all terminals are firm.