11

SINGLE & DOUBLE GIRDER TOP-RUNNING BRIDGES

WITH INDIVIDUAL MOTOR DRIVEN

END TRUCKS

P/N: 11532620 REV. AA

September 2018

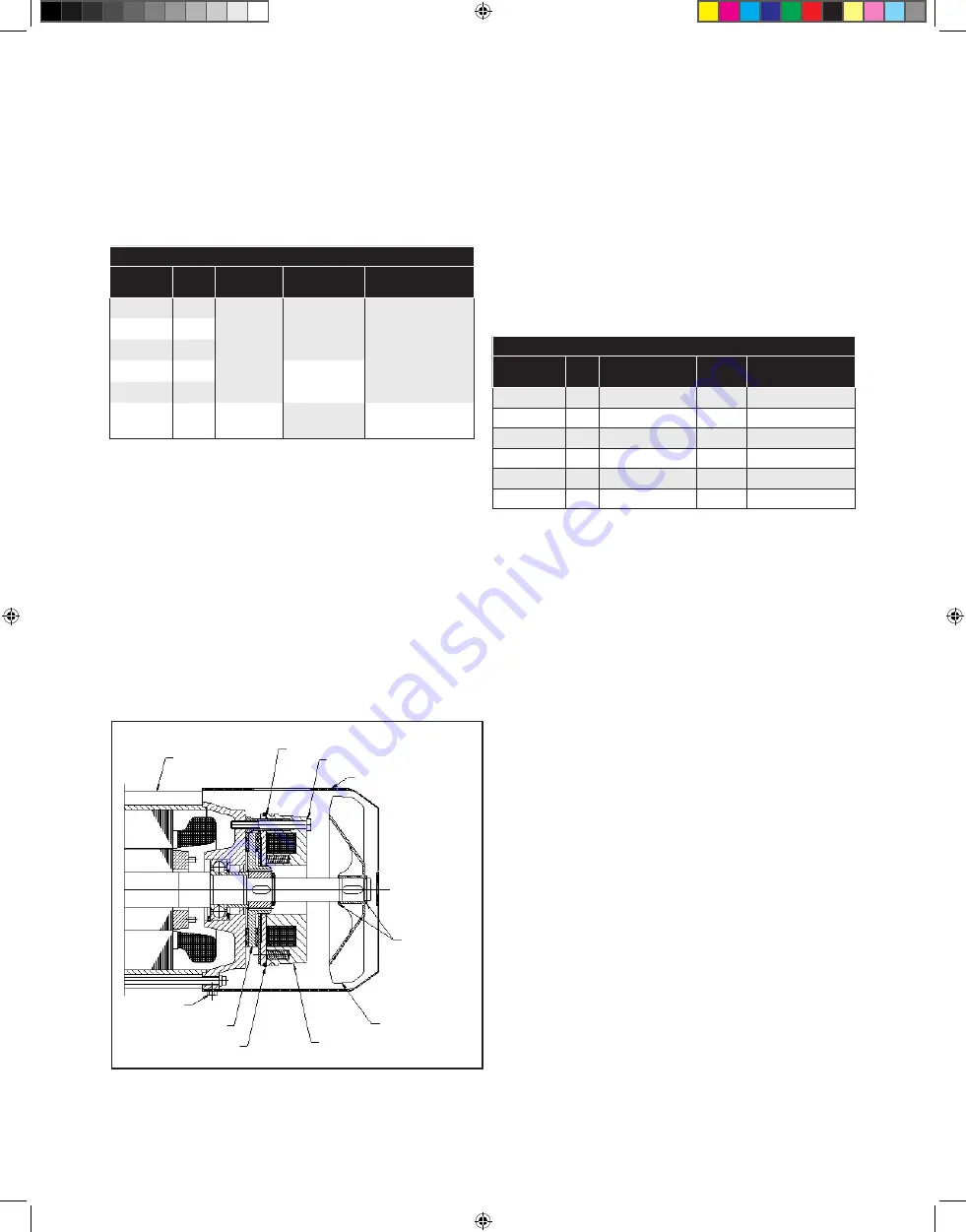

Brake Air Gap Inspection for ABM Gearmotors

To inspect brake air gap refer to figure 6:

1. Disconnect and lock out power supply

2. Remove brake cover

3. Carefully roll the o-ring back towards the magnet body exposing

the air gap between the armature plate and magnet. Use feeler

gauge and measure the gap between the armature plate and

magnet. If gap exceeds maximum allowed, replace the brake.

4. Roll o-ring back into place and re-install brake cover.

5. Turn power back on to crane and test brakes for proper

operation.

Brake Air Gap Inspection for Nord Gearmotors

The brake air gap is checked by placing a feeler gage between metal

anchor plate and the brake coil housing. This procedure is identical

even for the larger twin rotor brakes.

Procedure

1. Loosen the fixing screws that attach the brake to the motor’s end-

shield by approximately half a turn.

2. If required, the brake assembly may be loosened slightly from the

motor’s end shield by turning the threaded setting bolts (hollow

screws) that surround the fixing screws, counter clockwise, into

the brake coil housing.

3. Depending upon whether or not the air gap needs to be

decreased.

Motor End Bell

Air Gap

Brake Mounting Bolts

Retaining Rings

(where applicable)

Plastic Fan

(where applicable)

Shroud Bolt

Brake Disc

O-Ring

Magnet

Body

Shroud

Figure 6. Motor Brake

or increased, turn the fixing screws accordingly until the desired

nominal air gap is reached, as measured using the appropriate feeler

gauge. Turning the fixing screws clockwise allows the brake coil

housing to be moved towards the anchor plate and reduces the air

gap. Turning the fixing screws counter-clockwise allows the brake

coil housing to be moved away from the anchor plate and increases

the air gap.

4. If the setting bolts (hollow screws) were adjusted as suggested in

Step 2, re-secure the brake coil housing firmly against the motor’s

end shield by turning the setting bolts (hollow screws) clockwise,

out of the brake coil housing.

5. Tighten the fixing screws to the appropriate torque.

6. Re-check and measure the air gap in multiple locations to check

for appropriate spacing. Repeat the steps as needed until the

desired air gap spacing is uniform and consistent all the way around

the brake.

Brake Air Gap Inspection for FIR Gearmotors

Procedure

1. Remove the fan cover

2. Unscrew the (2) screws of the clamp and remove the fan.

3. Remove the retaining ring.

4. Unscrew the (4) M4 screws.

5. Remove the brake cover, with rubber bearing holder and the ball

bearing.

6. Check the air gap (0.4 ÷ 0.5 mm) in different positions, using the

feeler gauge.

7. If the air gap is different than the adjustment range:

a. Maintain locked the first nut (and the rotor shaft) with the

adjustable spanner.

b. Using a second adjustable spanner, completely unscrew the

second nut.

c. Clean the shaft thread from the old thread-lock.

d. Using the first adjustable spanner, adjust the air gap (maintain

locked the rotor shaft):

CW rotation = air gap (DECREASE)

CCW rotation = air gap (INCREASE)

e. Check using the feeler gauge in different positions.

f. Put a drop of LOCTITE 270 thread-lock on the shaft thread and

tighten the second nut with not in touch with the first nut.

g. Do not move/rotate the first adjustable spanner (first nut) to the

brake disk lining otherwise the air gap changes. Tighten the

second nut.

h. Check the air gap again (confirm the right adjustment), otherwise

unscrew lightly the second nut, adjust following points d – e and

finish following points g - h.

8. Position the brake cover using a bit of grease and tight the (4) M4

screws.

Nord Gearmotor

Motor

Horsepower

KW

Normal

Air Gap

Maximum

Air Gap

Brake Mounting

Bolt Torque

0.75

-

-

-

-

1.0

.75

0.2

0.6

4.4 lb-ft

1.5

1.2

0.2

0.7

7.4 lb-ft

2.0

1.5

0.2

0.7

7.4 lb-ft

3.0

-

-

-

-

5.0

-

-

-

-

AMB Gearmotors

Motor

Horsepower

KW

Normal

Air Gap

Maximum

Air Gap

Brake Mounting

Bolt Torque

0.75

.55

0.2 mm

(.008 in.)

0.3 mm

(0.12 in.)

3 Nm

(2.2 ft. lbs)

1.0

.75

1.5

1.2

2.0

1.5

0.4 mm

(0.16 in.)

3.0

2.2

5.0

3.7

0.3 mm

(0.12 in.)

0.9 mm

(.035 in.)

10 Nm

(7.5 ft. lbs)

MAINTENANCE CONTINUED

CMK_12322 Yale Rotating Axle End Truck Parts 11532619-REV AD_mec.indd 11

10/16/18 2:07 PM