6

7

CONNECTING THE PROBE/CABLE ASSEMBLY TO THE

INSTRUMENT

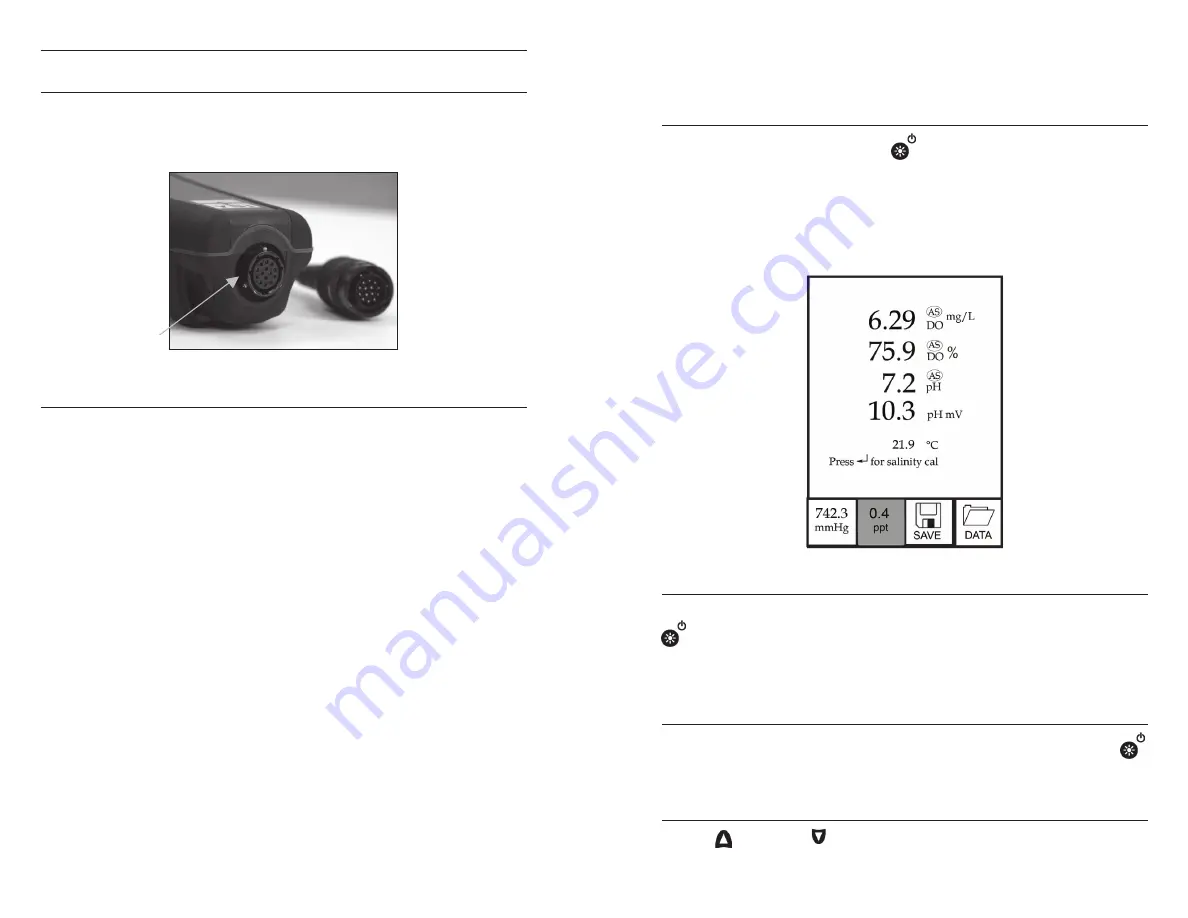

To connect the cable, align the keys on the cable connector to the slots

on the instrument connector. Push together firmly and then twist the

outer ring until it locks into place (figure 4). This connection is water-

proof.

Figure 4, Note the keyed connector.

MEMBRANE INSTALLATION

The sensing end of the dissolved oxygen sensor is shipped with a

protective cap that needs to be removed before using. Additionally, it

is very important to install a new membrane with electrolyte solution

onto the sensor after removing the cap.

Prepare the electrolyte solution according to the instructions on the

bottle. After mixing, allow the solution to sit for 1 hour. This will help

prevent air bubbles from later developing under the membrane.

Ensure you are using the correct electrolyte solution for your sensor.

Galvanic sensors utilize electrolyte with a light blue label on the bottle

and polarographic sensors utilize electrolyte with a white label on the

bottle. The dissolved oxygen sensor is supplied with cap membranes

specific to the sensor type ordered (polarographic or galvanic). 5913

and 5914 membrane kits are for Galvanic sensors and the 5908 and

5909 membrane kits are for Polarographic sensors.

Remove and discard or save the protective cap from the dissolved

oxygen sensor by pulling it straight off. Thoroughly rinse the sensor

tip with distilled or deionized water. Fill the cap membrane 3⁄4 full

of electrolyte solution, then tap the cap with a finger to release any

trapped air. Be careful not to touch the membrane portion of the cap.

Thread the membrane cap onto the sensor, moderately tight. Do not

use a tool. It’s typical for some of the electrolyte solution to spill over. It

is best to allow the new cap to remain on the sensor overnight before

calibrating. For detailed instructions on changing a cap membrane,

see the

Care, Maintenance and Storage section of this manual.

RUN SCREEN

Press the power/backlight key

to turn the instrument on. The

instrument will run through a self test and briefly display a splash screen

with system information before displaying the main Run screen (figure

5). A language, dissolved oxygen sensor and membrane selection

menu will display the first time the Pro1020 is powered on. See the

First Power On section of this manual for more information.

Figure 5, Run screen.

BACKLIGHT

Once the instrument is powered on, pressing the power/backlight key

will turn on the display backlight. The backlight will remain on until

the key is pressed again or after two minutes of not pressing any key

on the keypad.

POWERING OFF

To turn the instrument off, press and hold the power/backlight key

for three seconds.

NAVIGATION

The up and down arrow keys allow you to navigate through the

functions of the Pro1020.