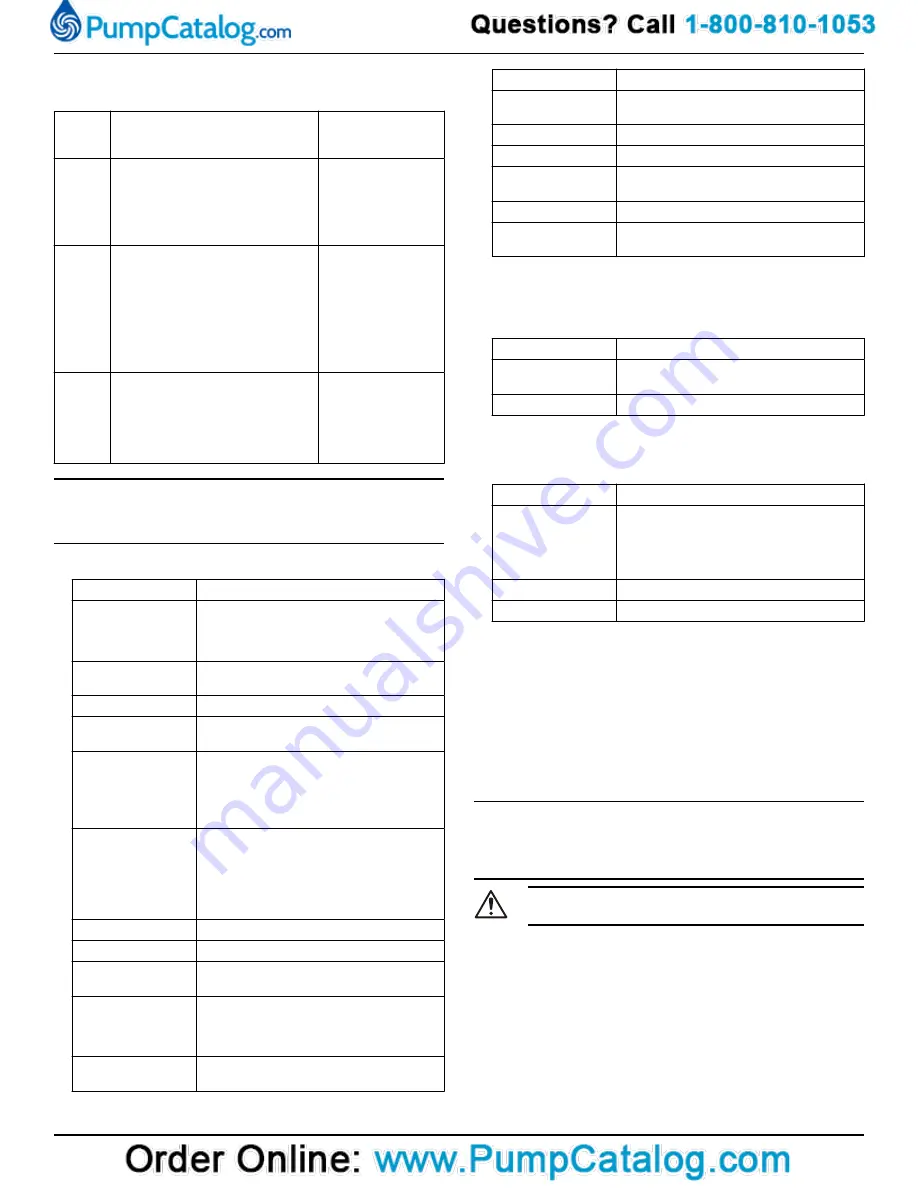

6.3 Service the pump

Type of

mainte-

nance

Purpose

Inspection interval

Initial in-

spection

A Xylem-authorized personnel

checks the pump condition. From

the results, the personnel recom-

mends the intervals for the periodi-

cal inspection and overhaul for the

installation.

Within the first year of

operation.

Periodi-

cal in-

spection

The inspection prevents operational

interruptions and machine break-

downs. The measures to increase

performance and pump efficiency

are decided for each application.

They can include such things as im-

peller trimming, wear part control

and replacement, control of zinc-an-

odes and control of the stator.

Up to every year

Applies to normal ap-

plications and operat-

ing conditions at me-

dia (liquid) tempera-

tures <40°C (104°F).

Over-

haul

The overhaul lengthens the operat-

ing lifetime of the product. It in-

cludes the replacement of key com-

ponents and the measures that are

taken during an inspection.

Up to every two years

Applies to normal ap-

plications and operat-

ing conditions at me-

dia (liquid) tempera-

tures <40°C (104°F).

NOTICE:

Shorter intervals may be required when the operating conditions are

extreme, for example with very abrasive or corrosive applications or

when the liquid temperatures exceed 40°C (104°F).

6.3.1 Inspection

Service item

Action

Cable

1. If the outer jacket is damaged, then re-

place the cable.

2. Check that the cables do not have any

sharp bends and are not pinched.

Connection to power Check that the connections are properly se-

cured.

Electrical cabinets

Check that they are clean and dry.

Impeller

1. Check the impeller clearance.

2. Adjust the impeller, if necessary.

Stator housing

1. Drain all liquid, if any.

2. Check the resistance of the leakage sen-

sor.

Normal value approximately 1530 ohms,

alarm approximately 330 ohms.

Insulation

Use a megger maximum 1000 V.

1. Check that the resistance between the

ground (earth) and phase lead is more

than 5 megohms.

2. Conduct a phase-to-phase resistance

check.

Junction box

Check that it is clean and dry.

Level regulators

Check the condition and functionality.

Lifting device

Check that the local safety regulations are

followed.

Lifting handle

1. Check the screws.

2. Check the condition of the lifting handle

and the chain.

3. If necessary, replace.

O-rings

1. Replace the coolant plug O-rings.

2. Grease the O-rings.

Service item

Action

Personnel safety de-

vices

Check the guard rails, covers, and other

protections.

Rotation direction

Check the impeller rotation.

Oil housing

Fill with new coolant, if necessary.

Terminal block/

closed end splice

Check that the connections are properly

tightened/connected.

Thermal contacts

Normally closed circuit; interval 0–1 ohm.

Voltage and amper-

age

Check the running values.

6.3.2 Overhaul

The basic repair kit includes O-rings, seals, and bearings.

For an overhaul, do the following in addition to the tasks listed un-

der Inspection.

Service item

Action

Support and main

bearing

Replace the bearings with new bearings.

Mechanical seal

Replace with new seal units.

6.3.3 Service in case of alarm

For information about indication values for sensors, see

Alarm source

Action

LD

1. Check for liquid in the stator housing.

2. Drain all liquid, if any.

3. Check the mechanical seal unit, the O-

rings, and the cable entry, if liquid was

found.

Thermal contact

Check the start and stop levels.

Overload protection Check that the impeller can rotate freely.

6.4 Replace the impeller

Required tools:

• 6 hexagon bit adapter with an extension of at least 125 mm (4.92

in.)

• Impeller puller

If applicable, contact your local sales and service representative for

correct type and size.

• Rod (wood or copper) for locking the impeller in place, if applica-

ble.

• Two crowbars, if applicable

NOTICE:

• When laying the pump on its side, do not allow the weight of the

pump to rest on any portion of the impeller. The impeller must not

be allowed to make contact with the concrete floor or other hard

and rough surfaces.

CAUTION: Cutting Hazard

Worn parts can have sharp edges. Wear protective clothing.

6.4.1 Remove the impeller: Non-clog and Vortex (H, M)

The instruction applies to pumps equipped with a Non-clog impeller or

a Vortex impeller with pressure class H or M.

1. Remove the suction cover:

a) Place the pump horizontally.

b) Remove the suction cover screws.

c) Remove the suction cover from the pump housing.

2. Remove the impeller:

a) Remove the impeller screw.

b) Remove the impeller and the conical sleeve.

1310 Installation, Operation, and Maintenance Manual

15

Summary of Contents for GOULDS 2GFK2412H

Page 1: ...Installation Operation and Maintenance Manual 90002801_3 0 1310...

Page 2: ......

Page 23: ......