5

XB9 TECH TIPS

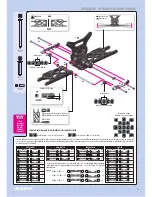

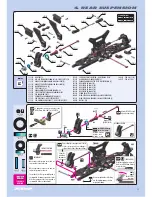

Before filling in the differentials with oil we suggest that you first check gear mesh as below. If there is too much or too little diff side play, this may create non-optimal gear mesh between the diff gear and the pinion

drive gear. This is easily resolved by inserting 1 or 2 of the included thin shims behind a diff outdrive ball-bearing, depending on how much play there is.

For easier gear mesh adjustments, optional S13 x 0.2

shims are used. These shims can be placed behind the

bearing which is quicker.

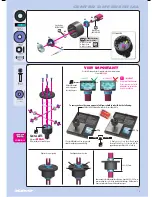

FRONT & REAR DIFF GEAR MESH ADJUSTMENT

The locaTIon oF The ShIm(S) dependS on wheTher you are TryIng To cloSe or open The gap:

Included ShIm

opTIonal ShIm

TO clOSE A wIDE GAp

TO OpEN A NARROw GAp

TIP

insert shim(s) here

insert shim(s) here

insert shim(s) here

TIP

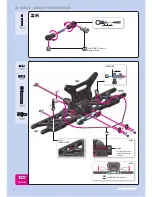

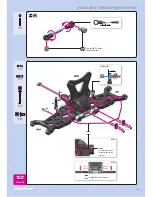

Tighten screw until pivot ball

is tight against block.

Lift ball joint until it snaps into

place over pivot ball. Ball joint

should move freely.

The finished joint.

Loosen and remove screw.

INSTALLING PIVOT BALLS INTO COMPOSITE BALL-JOINTS

Place the pivot ball on the ball joint

and use a screw to tighten it to an

engine mount or some other part.

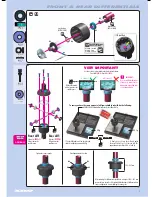

DRIVE SHAFT pINS SERVIcING

TIP

To enjoy the longest possible lifespan of the drive shafts and diff outdrives, it is extremely important to properly service the drive shaft pins.

Inspect the pins after every 3 hours of runtime. If the pins show any wear, replace them with new pins.

For easy and comfortable drive pin replacements use

#106000 hudy drive pin replacement Tool.

To replace the worn pins use only the

premium hudy drive pins #106050.

GRAPHITE PARTS PROTECTION

TIP

Follow this tech tip to protect the graphite parts.

Fine sandpaper

Use fine sandpaper

to sand smooth the

edges of all graphite

parts.

Apply CA glue to all edges

of the graphite parts.

Protect all XB9

Graphite Parts:

• Front shock tower

• Rear shock tower

• Steering plate

do not use drive shafts when

the pins are worn.

press out the worn pins.

press in new pins and

regularly inspect for wear.

962080

S 8x0.1

962081

S 8x0.2

To close a wide gap:

add 1 or 2 shims against diff

spur gear

To open a narrow gap:

add 1 or 2 shims on the other side

of the diff, away from spur gear

#962080 waSher S 8 x 0.1 mm (10)

#962081 waSher S 8 x 0.2 mm (10)

#962130

waSher

S 13 x 16 x 0.2 mm (10)

To close a wide gap:

add 1 or 2 shims against diff spur gear

To open a narrow gap:

add 1 or 2 shims on the other side of the diff, away

from spur gear

OpEN A NARROw GAp

clOSE A wIDE GAp

Summary of Contents for XB9

Page 1: ......