29

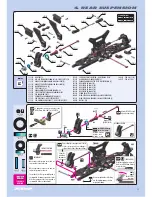

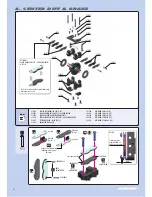

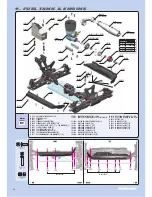

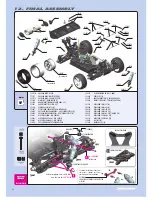

GEARING

GEAR MESH Adj.

CLUTCH SPRINGS

CLUTCH SHOE

911410

SHF M4x10

908308

SCH M3x8

908312

SCH M3x12

359050

BB 5x10x4

961025

S 2.5

962050

S 5x10x1

964073

S 7x10x0.2

964074

S 7x10x0.3

964075

S 7x10x0.5

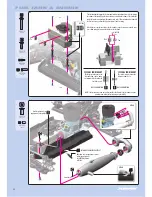

Please note that the engine is not parallel with the chassis centerline, so

that the clutchbell engages the spur gear at a slight angle. This is correct

and will not have any effect on handling, performance, or lifespan of

any parts.

2~2.5°

DETAIL

ANGLED ENGINE POSITION

CORRECT

7x10x0.2 / 0.3 / 0.5

3x8

5x10

2.5

Adjust engine

position to

achieve proper

gear mesh

Use appropriate shims to achieve proper

clutchbell endplay

11~11.2

mm

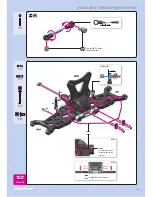

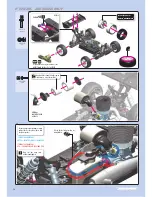

FUEL TANK & ENGINE

It is very important that your XB9 has properly-adjusted

gear mesh. Adjust the gear mesh so there is adequate (or

slightly larger) space between the spur gear and clutchbell

teeth. Adjust the gear mesh by sliding the engine mounts in

the slots of the chassis. You should be able to rock one gear

back and forth slightly while holding the other one firmly.

Be sure to check the gear mesh all the way around the spur

gear. Tighten the screws once the engine alignment and

gear mesh are correct, and then re-check the gear mesh to

ensure the engine mounts did not move.

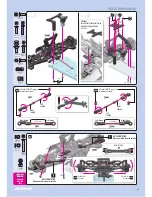

DETAIL

Tighten the clutch nut using

HUDY tool #107581

Hold the flywheel using HUDY Flywheel

Tool #182015

Use the cone included with your engine,

or use optional XRAY cone #358540

NOTE ORIENTATION

IMPORTANT!

Failure to use these shims

may cause the flywheel

pins to come out after

some time.

When installing the engine, first check that the drive shaft does not

touch the engine. If it does, remove some material from the engine

mount as shown to make some room between engine and shaft.

IMPORTANT

EXTREMELY IMPORTANT

These bearings must still be regularly serviced and

replaced when worn out.

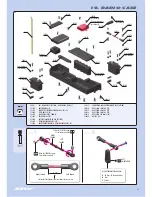

Note the orientation of the clutch shoes.

The short side of spring must be in the

groove of the flywheel nut.

Summary of Contents for XB9

Page 1: ......