TH series Touchscreen User Manual

Page 69 of 81

MANUL018R2V1

Device ID: the device number of import

device

Dynamic set: set the device ID in D

register.

Import control: control the import process

by M coil, when M is ON, the import

process starts.

Path/File: the CSV file name

Fix name: the import data are from the

same source file

Add ID after name: set the import file

name by the input value or the value in D

register.

Start ID: the import data head number.

Dynamic set: can set the head address in

D register.

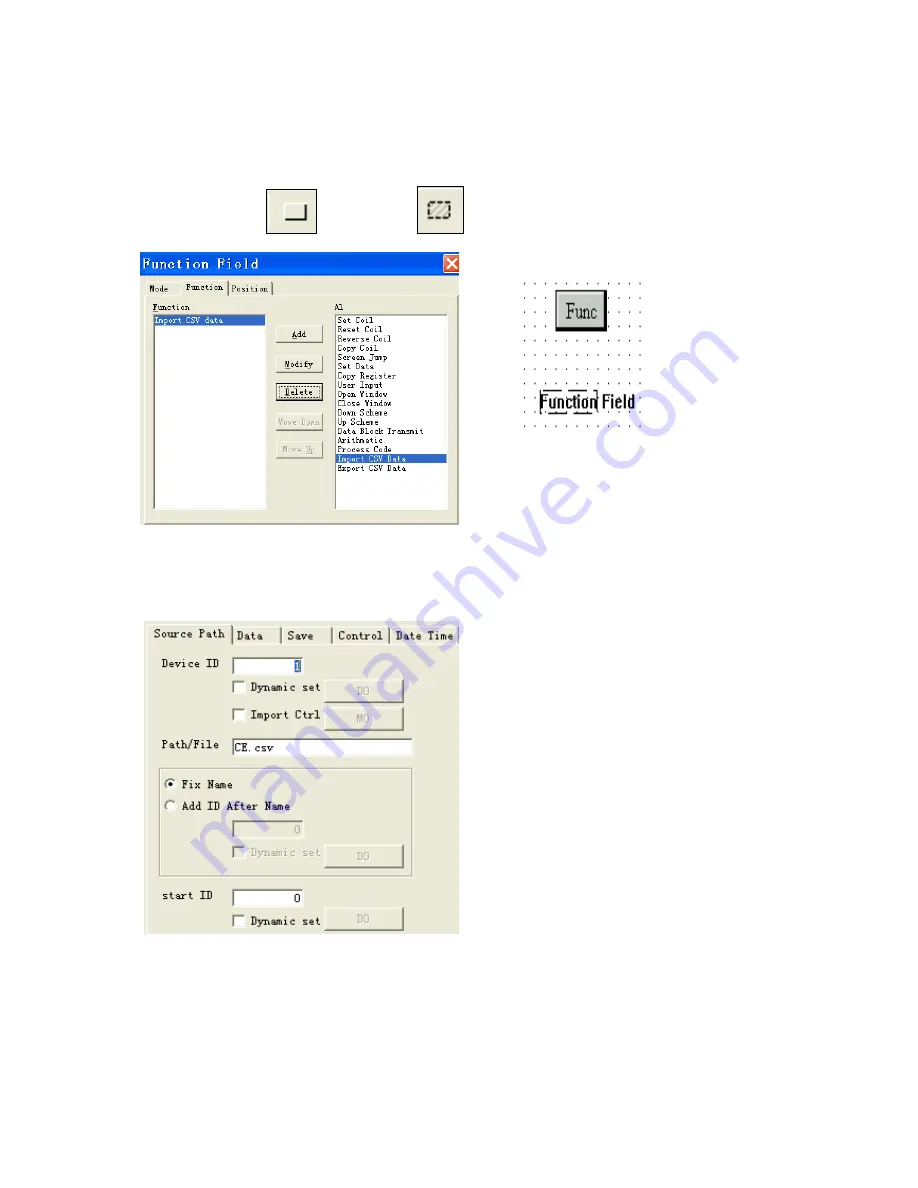

7-4-2 Import the C SV data

The purpose is to import the data from the SD card or U disk to TH register.

Step1:

Use function button

or function field

, select import CSV data function.

Step2:

Double click import CSV data, change the parameters as the following:

1. Source path tab

Please see the following picture: the import data when select start ID to 5 and 10.