Repairs and Adjustments

Phaser® 3500 Laser Printer Service Manual

4-4

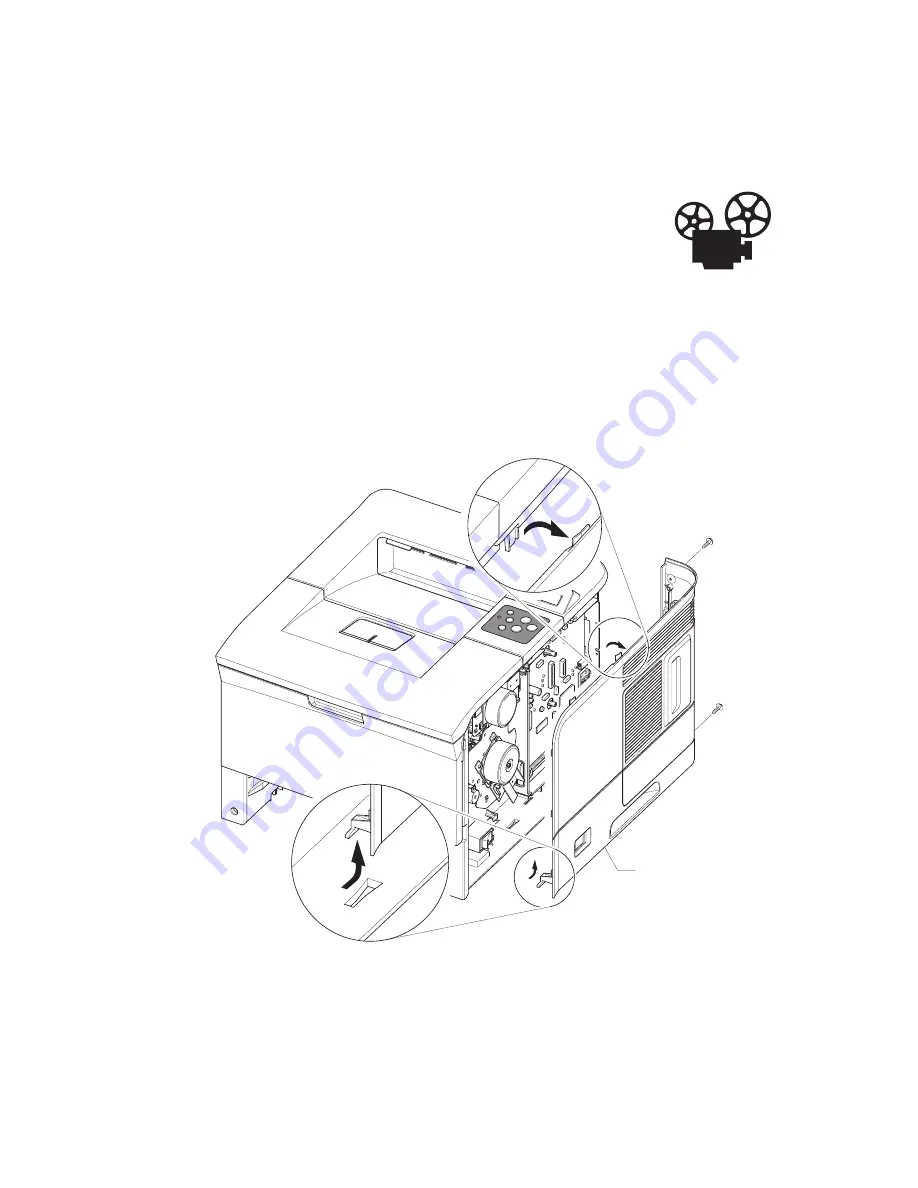

Covers

Right Cover

1.

Disconnect the power cord.

2.

Remove the Duplex Unit.

3.

Remove the 2 rear screws securing the Right Cover to the rear of the

printer.

Note:

In the next step, ensure the power switch is in the OFF position in order to free the

Right Cover.

4.

Slide the Right Cover towards the rear of the printer to release the 3 tabs, and remove it

from the printer.

Cover Right

s3500-068