Operation

18

Preparations

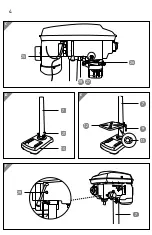

1. Fold the protective hood

14

up.

2. Use the enclosed chuck key

24

to loosen the jaws of the chuck

13

.

3. From below, insert the drill bit/tool vertically in the chuck opening and use the

chuck key to tighten the chuck jaws.

Then be absolutely sure to pull out the

chuck key

.

The drill bit/tool must be clamped in place in a central position.

• Only use drill bits and tools with a shank diameter of 1.5 to max.

13 millimetres with a cylindrical tool shank or taper shank.

4. Clamp the workpiece in the vice

19

included in the product contents.

5. Place the vice on the drilling table

12

.

6. Use the fixing screws, washers, spring washers and nuts

20

to secure the vice

(see chapter “Clamping the workpiece in the vice”).

7. Position the drilling table at the required height (see chapter “Adjusting the

drilling table”).

8. Fold the protective hood down again.

9. If applicable, adjust the length of the protective hood (see

Fig. G

) so that it offers

optimal protection (see chapter “Setting the height of the protective hood”).

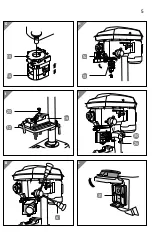

10. Set the speed so that it corresponds to the workpiece and the fitted drill bit/tool

(see chapter “Setting the speed”).

11. Unlock the emergency stop switch

17

by pushing it upwards.

The drill is now ready for operation.

Emergency stop switch

The emergency stop switch

17

is a safety fixture. It is

not intended to increase convenience of use. Normally,

you should always switch the drill off with the red off

switch

O

31

(see

Fig. L

).

If you press the emergency stop switch with a small

amount of pressure, the spindle will stop in place. The

chuck

13

and the fitted tool will stop rotating. After

the emergency stop switch has been pushed, it must

be manually unlocked. Otherwise, the drill cannot be

switched on again.

17