8

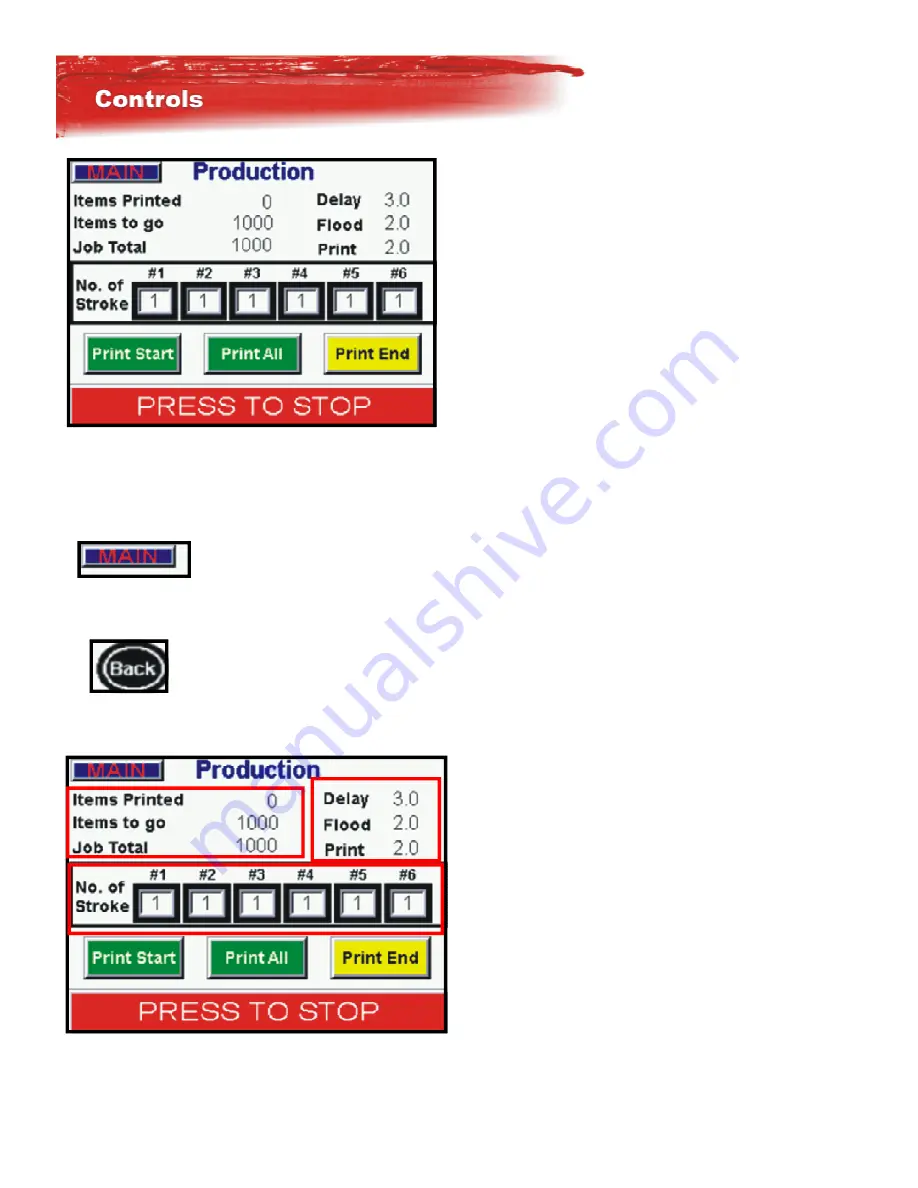

In the Producon screen there are several selecons. This is the normal screen that you will be running the ma-

chine from in producon. Changes can me made in here for # of head strokes , me allowed for delay, print or

flood. and even seeing items printed.

At the top leK corner of the screens you will see a Main switch. By

touching the screen here it will take you directly to the Main Menu

where all the short cut keys are.

At the top leK of some screens you will see a Back buIon. By touching this

buIon it will take you back to the previous screen

In this view of the touch screen there are 3 boxes that are out-

lined in red, each one of these is a Hot key by touching that

part of the screen it will link you straight to that selecon. If

you touch the mer Box, it will take you directly to the mer

screen, the same as the number of stroke seMngs and the

items to be printed. You can make changes with the machine

running.

Summary of Contents for Javelin PRO

Page 1: ...PN 67 1540 REV A 4 12...