-23-

W1751 25" Wide-Belt Sander

O

PE

R

AT

IO

N

S

Jet Air Flow

The air jet located at the air fork sends a stream of air

across the air fork and into the air stream receiver (see

Figure 18

).

As soon as the sanding belt obstructs this

stream of air, a piston changes the direction of belt

movement to the left. Your goal is to adjust this stream

of air so the system uses the least amount of air and

yet the machine still oscillates consistently and without

delay.

To adjust the jet air flow, do these steps:

1.

DISCONNECT THE SANDER FROM POWER.

2.

Adjust the air regulator to 75 PSI.

3.

Open both upper access doors on the sander, loosen

the sanding belt tension, and slide the belt so the

air stream is unobstructed.

4.

Loosen the jam nut and turn the jet adjustment

knob (

Figure 19

) clockwise until the air stream is

reduced to a minimum.

5.

Turn the jet adjustment knob counterclockwise,

and use a piece of cardboard to alternately block

and unblock the air stream until the upper drum

just begins to react and move left and right.

6.

Turn the jet adjustment knob counterclockwise an

additional

1

⁄

2

turn and tighten the jam nut.

7.

Now do the

Belt Tracking

procedure on

Page 24

.

Figure 18.

Air jet and air fork assembly.

Figure 19.

Jet adjustment knob.

Air Jet

Summary of Contents for SHOP FOX W1751

Page 2: ......

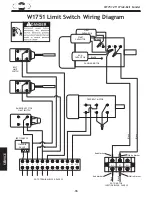

Page 40: ...38 W1751 25 Wide Belt Sander SERVICE W1751 Limit Switch Wiring Diagram...

Page 41: ...39 W1751 25 Wide Belt Sander SERVICE W1751 General Wiring Diagram...

Page 42: ...40 W1751 25 Wide Belt Sander PARTS Lower Cabinet and Sanding Motor...

Page 44: ...42 W1751 25 Wide Belt Sander PARTS Conveyor System...

Page 46: ...44 W1751 25 Wide Belt Sander PARTS Upper Roller System...

Page 48: ...46 W1751 25 Wide Belt Sander PARTS Platen and Sanding Drum System...

Page 50: ...48 W1751 25 Wide Belt Sander PARTS Upper Cabinet and Control Panel...

Page 59: ......

Page 60: ......