-15-

SETUP

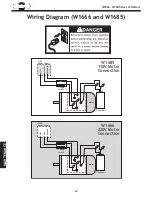

W1666, W1685 Dust Collectors

Figure 15.

Separator in correct position.

Figure 16.

Installing upper bag support.

Separator and Transfer

Hose

To install the separator and transfer hose, do these

steps:

1.

The separator has three tabs with threaded holes

along the bottom edge for mounting. Orient the sep-

arator so the holes align with supports and the inlet

is pointed toward the separator body.

See Figure

15.

2.

Secure the front and back supports using the hex

bolts and washers provided.

3.

Secure the upper bag support rod and the last sepa-

rator support to the separator as in

Figure

16

.

4.

Slide a wire hose clamp onto the end of the transfer

hose.

5.

Slide the transfer hose end over the inlet for the

collector making sure the end passes the ridge on

the inlet by 1

1

⁄

2

".

6.

Position hose clamp over the hose and the inlet

making sure the clamp is

3

⁄

4

" from the end of the

hose and tighten the screw on the clamp (see

Figure

17

).

7.

Slide the second hose clamp onto the free end of

the hose.

8.

Slide the end of the transfer hose onto the outlet of

the impeller housing. The hose should go on as far

as possible.

9.

Slide the hose clamp within

3

⁄

4

" of the end of hose,

and tighten the screw on the clamp.

Never bypass the dust collector or and duct the transfer

hose outside without using dust collection bags, or move

the separator to a remote location and use a longer

transfer hose. Any modification can damage the dust

collector motor and create an unsafe condition.

Figure 17.

Securing transfer hose with clamp.

Summary of Contents for Shop Fox W1666

Page 23: ... 23 PARTS W1666 W1685 Dust Collectors Parts Diagram W1666 and W1685 ...

Page 26: ... 26 PARTS W1666 W1685 Dust Collectors Notes ...

Page 27: ... 27 PARTS W1666 W1685 Dust Collectors Notes ...

Page 31: ......

Page 32: ......