24

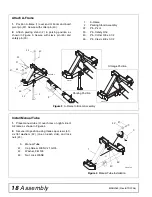

Assembly

MAN0160 (Rev. 8/19/2005)

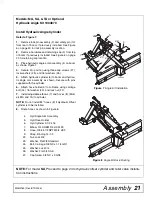

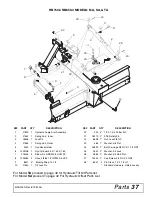

Model: SA or Optional Offset Kit 1004872

Install Hydraulic Offset Cylinder

Refer to Figure 13.

NOTE:

Hydraulic angle cylinder must be installed with

this offset kit.

1.

Install hydraulic angle kit as instructed on page

21. Remove 84” hoses from angle cylinder if previ-

ously installed.

2.

Attach hydraulic cylinder (3) between A-Frame

and boom as shown in Figure 13. Secure with pins

supplied with the cylinder.

3.

Install adjustable elbows (4) to cylinder (3).

4.

Remove bracket (1) and hardware if previously

installed.

5.

Install 45–degree elbows (5) into relief valves (2).

Position elbows outward as shown.

6.

Attach both valve blocks (2) and bracket (1) to

boom using two cap screws (21), four flat washers

(22), two lock washers (23), and hex nuts (24).

7.

Attach hoses (10) to elbows (5) as shown.

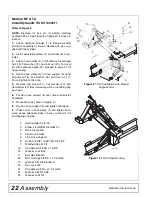

8.

Attach hoses (8 & 9) to back side of relief valves

(2) and offset cylinder (3) as shown in Figure 14.

9.

Attach hoses (6 & 7) to back of relief valves (2)

and angle cylinder as shown in Figure 14.

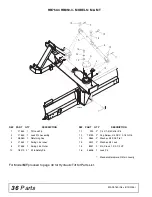

1.

Bracket - SMV Sign

2.

Valve Double Relief 1600 psi

3.

Hyd Cylinder 3-1/2 x 16

4.

Elbow, 3/4 ORBM 3/4 JICM 90

5.

Elbow, 3/4 JICM x 3/4 ORMB 45

6.

Hose, 3/8 18 3/4 ORBM 3/4 JICF

7.

Hose, 3/8 24 3/4 ORBM 3/4 JICF

8.

Hose, 3/8 28 3/4 ORBM 3/4 JICF

9.

Hose, 3/8 34 3/4 ORBM 3/4 JICF

10.

Hose, 3/8 66 1/2 NPTM 3/4 JICF

11.

Binding Strap, 14-1/2

21.

Cap Screw, 5/16 NC x 5-1/2 GR5

22.

Washer, Flat 5/16 Standard

23.

Washer, Lock 5/16

24.

Nut, Hex 5/16 NC

Figure 13

Offset Kit Installation

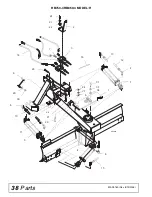

Figure 14

Hose Connection

6

7

4

8

9

11

2

5

10

21

3

1

24

23

CD5982

Offset

Angle

C

D

B

A

B

A

C

D

CD5997

To Tractor

Offset Couplers

To Tractor

Angle Couplers