7. Once fuel has been loaded, close the door and

leave the air inlet control fully open until

fire

is well

established (at least 15–20 minutes) being careful

not to over

fire

(if any of the exterior parts of the

stove or chimney connections begin to glow you

are ov

er fi

ring the stove).

8. Re-adjust the primary air inlet control to the desired

burn rate. For “high” setting pull the primary air con

-trol (center control) all the way out, for “low” push all

the way back. (If excessive smoke

fills the fireb

ox,

open air inlet control slightly until

flames

resume

and wood is

sufficiently

ignited.) The basic rule of

thumb is “closed (push in) = low,” “half way open =

medium” and “fully open (pull out) = high.”

9.

CAUTION: Always be sure to securely close the

front door when you are satisfied with the quality

of the fire burn. Firmly rotate door handle counter

clock-wise until the handle stops rotation. Never

leave stove unattended with door open!

-

CAUTION: DO NOT OVER FIRE APPLIANCE.

YOU ARE OVER FIRING IF THE CHIMNEY

CONNECTORS OR STOVE GLOWS RED. CLOSE

THE DOOR AND IMMEDIATELY SHUT ALL AIR

CONTROLS (PUSH IN) TO REDUCE THE AIR

SUPPLY AND SLOW DOWN THE FIRE.

CAUTION: SLOW BURNING FIRES AND EXTEND-

ED USE MAY CAUSE EXCESSIVE CREOSOTE

BUILDUP. IGNITION OF CREOSOTE OR OVER

FIRING MAY CAUSE A CHIMNEY FIRE. CHIMNEY

FIRES BURN EXTREMELY HOT AND MAY IGNITE

SURROUNDING MATERIALS. IN CASE OF A

CHIMNEY FIRE CALL THE FIRE DEPARTMENT

IMMEDIATELY.

ADDING FUEL

If the coal bed is not hot and glowing, rake the coals

to the front of the stove, close the door and adjust the

primary air inlet control to the wide open position. Let

the coals re-heat for 10–15 minutes. When hot and

glowing, spread them out and place your next fuel load

into the stove (make sure no coals or ashes block the

LPAO). Leave the primary air inlet control in the wide

open (pulled out) position for 15–20 minutes.

Fuel load size can vary but should be kept

1–2˝

(25mm-50mm) below the secondary air tubes. Also

position the fuel to leave space so the air from the inlet

can work between the pieces of fuel. This reduces the

time it takes for new fuel to burn properly.

1. When refueling, increase the center primary air

control to the fully open (pulled out) position. When

fire

brightens, slowly and carefully open the door.

This procedure will prevent unburned gases from

igniting causing smok

e and flame spillag

e.

2. When adding fuel be careful not to hit, bump or

damage the secondary air tubes at the top of the

fireb

ox.

3. Add fuel being careful not to overload or over

fire

the stove.

4. When adding fuel be careful not to smother the

fi

re.

Do not build

fires

against glass and make sure the

coal bed does not obstruct the air inlet. Do not load

fuel to a height or in such a manner that it creates

a hazard when opening the door.

5. Close the feed door and secure tightly.

6. Adjust the air inlet control as described above.

7. Empty ashes regularly. Do not allow ashes

to pile up (see Safety Instructions #14

n

o

page 2.)

8. Properly dispose of hot ashes (see Safety

Instructions, item #14 on page 2.)

9. Do not over

fi

re the stove (over

fi

ring is when

any part of the stove exterior or chimney

connections glow).

CREOSOTE – FORMATION AND NEED FOR

REMOVAL

CAUTION: RISK OF FIRE When wood is burned

slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form

creosote. The creosote vapors condense in the

relatively cool chimney

flue

of a slow-burning

fir

e. As a result, creosote residue accumulates

on the

flue

lining. When ignited this creosote

makes an extremel

y hot fir

e.

The chimney connector and chimney should

be inspected at least once every two months

during the heating season to determine if a

creosote buildup has occurred.

If creosote has accumulated (3mm or more)

it should be removed to reduce the risk of a

chimne

y fir

e.

Failure to remove creosote may result in ignition

and may cause a house/building

fir

e. Creosote may be

continued on next page

OPERATING INSTRUCTIONS

...continued

19

Summary of Contents for WS-TS-1500

Page 6: ...6 Minimum Clearances for installation according to UL 1482 US ULC S627 CAN A ...

Page 7: ...7 Top A A Alcove ...

Page 8: ...philips BLOWER ATTACHMENT 8 4 places A GASKET ...

Page 9: ...9 WS TS 2500 23 8 6 ...

Page 10: ...10 6 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 23: ...23 BAFFLE REMOVAL ...

Page 24: ...24 BAFFLE REMOVAL ...

Page 25: ...SERVICE PARTS 25 ...

Page 26: ...SERVICE PARTS 26 ...

Page 27: ...SERVICE PARTS 27 ...

Page 28: ...SERVICE PARTS 28 ...

Page 29: ...SERVICE PARTS 29 ...

Page 30: ...SERVICE PARTS WS TS 2500 30 ...

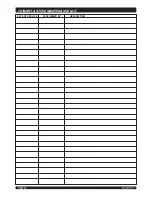

Page 33: ...DATE OF SERVICE PERFORMED BY DESCRIPTION CHIMNEY STOVE MAINTENANCE LOG 33 ...

Page 35: ...Warranty 35 ...

Page 36: ...36 www woodprostoves com 2 ...