Woodley Equipment Company

–

+ 44 (0) 1204 669033

–

[email protected]| Page 6

S

ETTING OR

M

ODIFYING A

S

AVED

C

YCLE

Up to 10 cycles can be named, programmed for time, speed and braking and saved in memory. The top screen

alternates between cycle name and speed when not in programming mode.

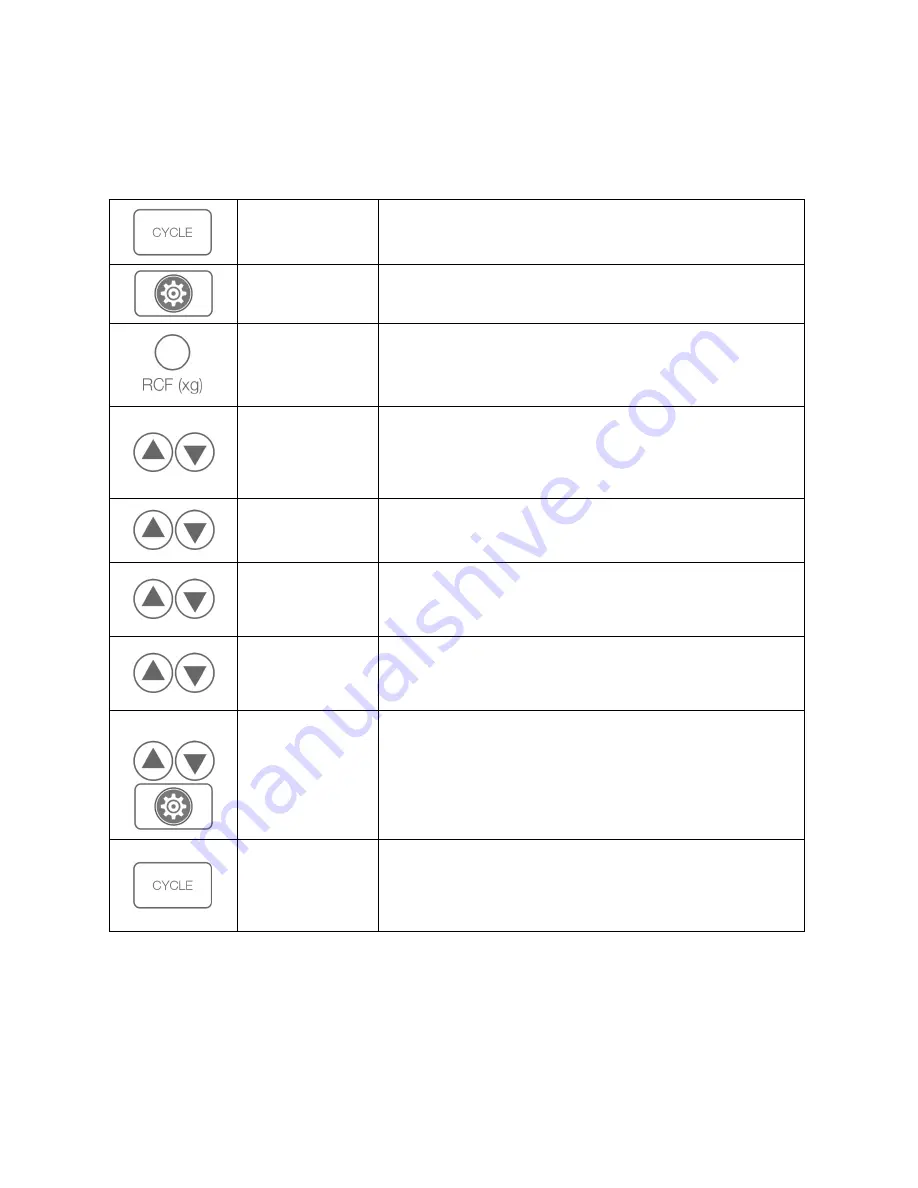

Cycle Selection

Press the CYCLE button until the number for the cycle to be

programmed or changed is displayed.

Enter Settings

Mode

Press the GEAR button. The word “Speed” appears on the top

screen.

Setting by G-force

(Recommended)

While the top screen displays SPEED, press and hold the RCF (xg)

button while changing the displayed setting, using the up and

down buttons next to the bottom screen. The RPM will

automatically adjust.

Setting Speed

(Alternate)

If the G-force is set correctly, the speed does not need to be set

separately. To change the speed (RPM) shown on the bottom

display, use the up and down buttons next to it. The G-force will

adjust automatically and can be verified by pressing the RCF

button.

Setting Time

Navigate with the down key next to the top screen until it shows

“Time”. Press the up and down buttons next to the bottom

TIME

display to adjust time.

Change Brake

Values

Navigate with the down key next to the top screen until it shows

“Brake”. To change the value shown on the BRAKE display, use the

up and down buttons next to the BRAKE screen.

Turn Beeper

On or Off

Press the up and down keys next to the upper screen until

“Beeper” shows on the upper screen. Switch ON or OFF with the

keys next to the lower screen. This setting will apply to all cycles.

Naming the Cycle

Navigate to the cycle name with the UP and DOWN arrows. The

current name of the cycle is displayed and can now be changed.

Press the START button. The * indicates the character selected.

Change it to the desired character with the up and down buttons,

then move to the next character with the right arrow >. Repeat.

Press the GEAR button to get back to the main programming

menu. A beep indicates that the name has been saved.

Save and Exit

Settings Mode

Press and hold the CYCLE button until you hear a double beep.

The new parameters will be saved to the cycle number displayed

on the screen to the right.

Note: if the GEAR button is pressed before the CYCLE button, all

changes will be lost.

D

ELETING A

C

YCLE

To delete a selected cycle, press the GEAR button and simply set either TIME or SPEED to zero and save by pressing

the CYCLE button.

Summary of Contents for Clinispin HORIZON 12 Flex

Page 1: ...Clinispin HORIZON 12 Flex 24 Flex Operator s Manual...

Page 2: ......