5.2 ADJUSTING THE TAILSTOCK

5.3 CHANGING SPINDLE SPEEDS

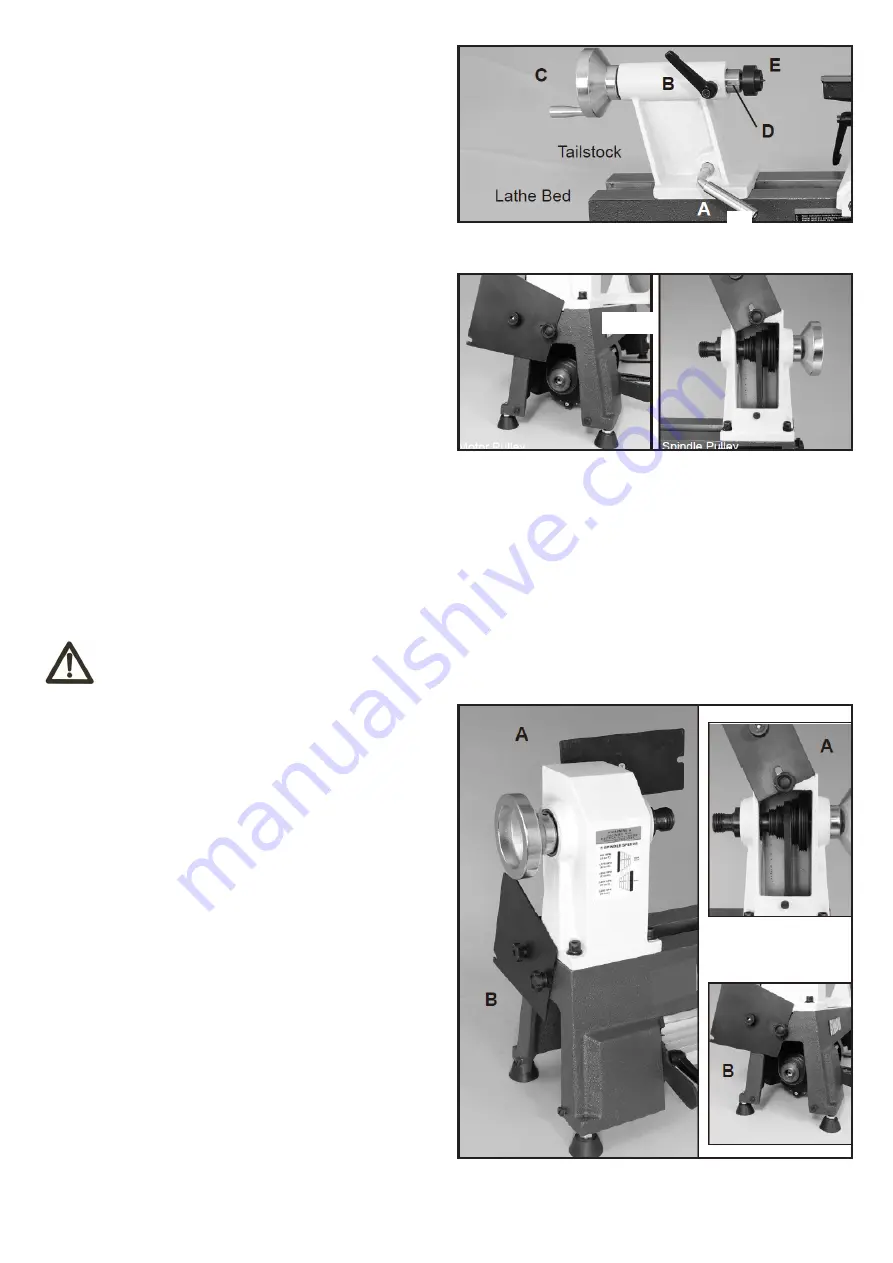

5.4 CHANGING THE DRIVE BELT

- Loosen the locking lever (A) to move the tailstock along

the lathe bed to the desired position for holding your

work piece. Then tighten the locking lever to secure the

tailstock on the bed. FIG. 5.2.

- To adjust the clamping action of the tailstock on the bed,

adjust the lower locking nut. See the instructions listed

FIG. 2.

- To adjust the tailstock spindle in or out to hold or release

your work piece, loosen the locking lever (B) and turn the

hand wheel (C). The tailstock spindle (ram) (D) will travel

from 0” to 1-3/4”. When the tailstock spindle holding the

live center (E) is in a desired position, tighten the locking

lever (A). FIG. 5.2

The lathe features five step motor and spindle pulleys to

provide different spindle speeds. Open the two access

covers to change spindle speeds. FIG. 5.3.

To change the belt, the whole spindle shaft needs to be

shifted right, out of the headstock, towards the tailstock.

This will allow the new belt to be slipped over the spindle

and onto the spindle pul-ley. Then the whole spindle shaft

assembly can be re-installed so turning can be resumed.

- Unplug the lathe from the power source.

- Remove any accessories from the spindle -spur center,

pen mandrel, chuck, faceplate, etc..

- Open the rear spindle pulley cover (FIG. 5.4,A) and the

lower, side motor pulley cover (B) to gain access to the

drive belt and pulleys that are inside of the headstock and

bed casting.

- Loosen the motor mount locking lever handle (FIG. 5.3,

F) and lift the motor mounting plate lever (G) to loosen the

tension on the belt. The belt can now be removed from

the lower motor pulley (FIG. 5.4, B).

- Loosen the set screws that attaches the hand wheel (C)

to the spindle, and remove the hand wheel. FIG. 5.5.

- Remove the set screw(s) that attaches the spindle pulley

to the spindle. The pulley should now be loose on the

spindle. FIG. 5.4 , A.

Fig.5.2

Fig.5.3

Fig.5.4

-11-

WARNING

Do not put excess tension on the drive belt or excess wear or damage to the bearing or motor

may result.

- With the access covers open, loosen the locking lever handle (F) that secures the motor in place, and raise the motor

mounting plate lever (G) to release the belt tension on the motor and spindle pulleys.

- Check the speed and belt position chart to determine the spindle speed required for your turning. Then move the drive

belt to the desired pulley combination.

- With the locking lever handle and motor being loose, the motor’s weight will provide the proper tension on the drive

belt. Re-tighten the locking lever and close access covers.