Sawmill Alignment

Blade Installation And Alignment

Sawmill Alignment

HDSdoc091108

5-3

5

saw head.

2.

Start the engine (or motor).

3.

Pull lightly on the clutch handle, rotating the blade until the blade positions itself on the wheels.

WARNING!

Do not spin the blade wheels by hand. Spinning the

blade wheels by hand may result in serious injury.

4.

Release the clutch handle to stop the blade. Turn off the engine, remove the key and check the

position of the blade on the blade wheels.

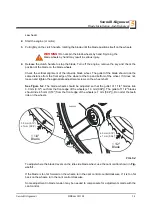

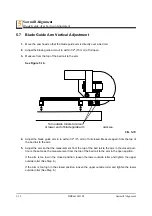

Check the vertical alignment of the idle-side blade wheel. The gullet of the blade should ride the

same distance from the front edge of the wheel at the top and bottom of the wheel. If it does not,

loosen and tighten the appropriate adjustment screws on the wheel shaft.

See Figure 5-2.

The blade wheels should be adjusted so that the gullet of 1 1/4" blades ride

3.0 mm (0.12") out from the front edge of the wheels (± 1.0 mm[0.04"]). The gullet of 1 1/2" blades

should ride 4.5 mm (0.18") from the front edge of the wheels (± 1 mm [0.04"]). Do not let the teeth

ride on the wheels.

To adjust where the blade travels on the idle-side blade wheel, use the cant control shown in

Fig-

ure 5-1.

If the blade is too far forward on the wheels, turn the cant control counterclockwise. If it is too far

back on the wheels, turn the cant control clockwise.

Some adjustment in blade tension may be needed to compensate for adjustments made with the

cant control.

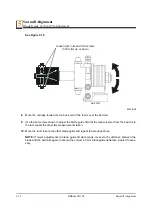

FIG. 5-2

SM0044D

1 1/2"

Blade

± 1 mm (0.04”)

1 1/4"

Blade

3.0 mm (0.12”)

± 1 mm (0.04”)

4.5 mm (0.18”)

Summary of Contents for LT40 DH

Page 1: ......

Page 2: ......

Page 69: ...Maintenance Carriage Track Wiper Scrapers Maintenance HDSdoc091108 3 5 3 FIG 3 3 ...