24

CLEANFIRE OUTDOOR FURNACE • OWNER'S MANUAL

5. The combustion air inlets must be kept open and clear of ash and coals

to allow the furnace to operate properly. If needed, remove enough ash

to keep the combustion air inlets free of obstruction.

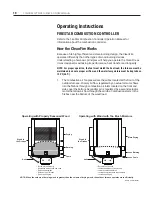

NOTE: It is important to understand that when the water temperature setpoint (185°F)

is reached, the combustion air is shut off until the water temperature drops to the

setpoint minus the differential setting. During this cycle-off time there will be no

active fire in the firebox. If the firebox door is opened, the wood might begin to

burn again but will be shut down when the door is closed if the water temperature is

above the setpoint. If the door is opened and closed when the water temperature is

below the setpoint the fan will cycle on again to achieve the setpoint even though the

differential point has not been reached. If the combustion cycle is activated with the

water temperature at least to the differential below setpoint and the fire is not actively

burning when the door is closed, first confirm that proper operating and maintenance

procedures are being performed before considering testing mechanical components.

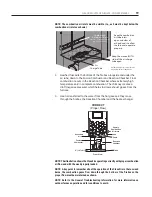

6. When refilling the firebox, the new wood load will ignite quickly and

burn more efficiently if these instructions are followed. This will prevent

creosote buildup in the heat exchanger, air channels or primary elbow.

The operating procedures will maintain good air flow and very efficient

combustion.

DAILY

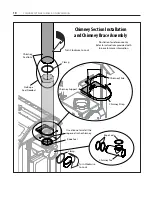

• Run the cleaning rod through the ash and coal bed and along both

sides of the air tube as shown on previous page to keep ash loose.

Use care near the refractory. This will allow excess ash to flow down

into the Reaction Chamber. If the coal bed/remaining wood is more

than 4 inches deep, it may be necessary to use the cleaning rod to

open a passage through the coals on each side of the air tube. Air

flow down past the air tube is essential for a good combustion rate

to be maintained. To confirm adequate air flow, cautiously open the

Reaction Chamber door to visually identify the combustion air flow

while the furnace is in a burn cycle with the fan on and the bypass

closed.

• To ensure the fire will maintain good combustion, it is important to

refill the firebox when an adequate amount of the previous wood load

is remaining (enough to provide enough heat and fire to dry and ignite

the new wood load). If the coals burn out from under the new wood

load and are unable to keep the fire going, there are not enough coals

and wood left from the previous load. Enabling the Easy Refire mode

will help keep part of the wood load for a quicker, more efficient fire

up after reloading. Easy Refire is enabled as default setting on version

6.72 and later.

• Be sure to fill the firebox with enough wood so there is adequate wood

left the next time you load to dry and ignite the new wood.

• Keep in mind that burning dry, well-seasoned wood requires less coals

to ignite the new wood load.