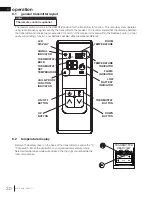

This appliance comes equipped with our “Night Light”.

If in the event the lamp or lens needs to be replaced, follow these instructions.

Disconnect the two wire leads at the wire nut. Remove the four screws

securing the accent light assembly from the relief door. Disassemble the

light and the lamp now can be accessed

Note: Do not handle the lamp (bulb) with bare fi ngers, protect with

a clean dry cloth.

The lamp will pull straight out of the socket. Replace with Wolf Steel

parts only, as lamp and lens are special “high temperature” products.

When re-installing, ensure integrity of gasket seal.

THE FIREBOX MUST BE SEALED.

When re-assembling the light assembly, care must be taken

with all gaskets.

“Light Leakage” from above the cast doors may

be noticed. The holes in the lamp housing are

necessary for ventilation and must not be covered.

10.2 NIGHT LIGHT REPLACEMENT

GASKET

GLASS LENS

GASKET

SHEILD

RAIL

RAIL

WIRE NUT

COVER PLATE

RELIEF

DOOR

10.3 PILOT INJECTOR AND ORIFICE REPLACEMENT

ORIFICE

LOCATION

BURNER

ASSEMBLY

This must be carried out by an AUTHORIZED REPRESENTATIVE OF WOLF STEEL

LTD. or a QUALIFIED GAS INSTALLER in accordance with local codes or in the

absence of local codes with the requirements of the provincial / state authorities having

jurisdiction and in accordance with the requirements of the CAN1-B149 Installation Code

in Canada and the ANSI Z223.1 National Fuel Gas Code in the United States.

A.

Turn off the electrical and gas supply to the appliance.

B.

Remove the cast front, glass viewing door and log set.

C.

Remove the 2 securing screws. Slide the burner assembly to the right and lift

out.

D.

Using a deep socket wrench, remove the main burner ori

ce. A back-up wrench

must be used on themanifold, located below the housing to ensure that the

aluminum tubing does not twist or kink. Replace the correct burner ori

ce using

pipe thread compound.

E.

Loosen nut and replace with appropriate injector

F.

Reinstall the burner ensuring that the Venturi tube

ts over the ori

ce.

G.

Turn on the gas supply and check for gas leaks by brushing on a soap and water solution.

Do not use open fl ame.

H.

Replace the log set. Then light the pilot and main burner to ensure that the gas lines have

been purged.

I.

Replace the glass viewing door and cast front. Turn on the electrical supply to the appliance.

!

WARNING

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT

WITH THE GLASS DOOR OPEN OR REMOVED.

37.1C

• Access the blower, if equipped and clean using a soft brush and vacuum.

• Re-assemble the various components in reverse order.

• Inspect the relief system. The appliance relieves through the main glass door or through the

aps on the

rebox top. Ensure they open freely, and close sealed.

• Check the gas control valve pilot and Hi / Lo knobs move freely (if equipped) – replace if any stiffness in

movement is experienced.

• Check for gas leaks on all gas connections up and downstream from the gas valve including the pilot tube

connections.

W415-1332 / A / 11.21.14

35

EN

8.2 pilot injector and orifice replacement

This must be carried out by an AUTHORIZED REPRESENTATIVE OF WOLF STEEL

LTD. or a QUALIFIED GAS INSTALLER in accordance with local codes or in the

absence of local codes with the requirements of the provincial / state authorities having

jurisdiction and in accordance with the requirements of the CAN1-B149 Installation Code

in Canada and the ANSI Z223.1 National Fuel Gas Code in the United States.

A.

Turn off the electrical and gas supply to the appliance.

B.

Remove the cast front, glass viewing door and log set.

C.

Remove the 2 securing screws. Slide the burner assembly to the right and lift out.

D.

Using a deep socket wrench, remove the main burner orifice. A back-up wrench

must be used on themanifold, located below the housing to ensure that the

aluminum tubing does not twist or kink. Replace the correct burner orifice using

pipe thread compound.

E.

Loosen nut and replace with appropriate injector

F.

Reinstall the burner ensuring that the Venturi tube fits over the orifice.

G.

Turn on the gas supply and check for gas leaks by brushing on a soap and water

solution.

Do not use open flame.

H.

Replace the log set. Then light the pilot and main burner to ensure that the gas

lines have been purged.

I.

Replace the glass viewing door and cast front. Turn on the electrical supply to the

appliance.

• Always light the pilot whether for the first time or if the gas supply has run out with the glass door open or

removed.

!

WARNING

!

WARNING

Buff lightly with a clean dry soft cloth to remove accumulated dust or fi ngerprints. Clean both sides of the glass

after the fi rst 10 hours of operation with an ammonia-free glass cleaner.

Thereafter, clean as required. If the glass is not kept clean permanent discoloration and / or blemishes may

result. Contact you local authorized dealer / distributor for complete cleaning instructions.

Razor blades, steel wool, or other metallic objects must not be used on both surfaces of the glass. Doing so

can remove a thin layer of metal from the razor blades, steel wool, or other metallic objects that may then be

deposited onto the coating. This can result in a discoloured stain or scratch-like mark. More importantly, this can

scratch the glass surface, thereby reducing its strength.

Do not operate the appliance with broken glass, as leakage of fl ue gases may result.

Contact your local authorized dealer / distributor for complete cleaning instructions.

If the glass should ever crack or break while the fi re is burning, do not open the door until the fi re is out. Do not

operate the appliance until the glass has been replaced. Contact you local authorized dealer / distributor for

replacement parts.

DO NOT SUBSTITUTE MATERIALS.

5.1A

Vinegar-based glass cleaners have demonstrated an ability to provide a clean, streak free glass surface.

note:

• Do not clean glass when hot! Do not use abrasive cleaners to clean glass.

8.3 care of glass

5.1.3

This appliance is factory equipped with 5mm ceramic glass. Use only replacement parts as supplied by the

appliance manufacturer.

DO NOT SUBSTITUTE MATERIALS.

W415-4016 / 08.09.21

EN

36

maintenance