Maintenance

4104

−

1/A1

Winterthur Gas & Diesel Ltd.

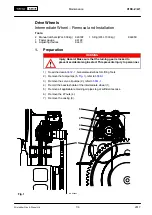

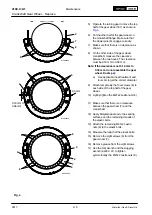

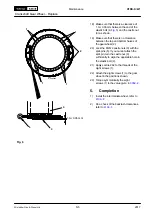

Drive Wheels

Running and Backlash Clearances and Tooth Condition

Tools:

1 Feeler gauge

94122

1 Dial gauge

1 Micrometer

1 Lead wire Ø 1.5 mm

1.

General

On new engines during the running-in period, you must do a visual check of the gear

wheels after approximately one and two operation hours. You must do the same

checks on used engines that have new gear wheels installed.

2.

Checks

WARNING

Injury Hazard: Before you operate the turning gear, make sure that

no personnel are near the flywheel, or in the engine.

1) Use the turning gear to turn the crankshaft while you do an inspection of all teeth.

2) Set to on the service pump.

3) Make sure that oil flows freely from all nozzles.

4) Set to off the service pump

5) Make sure that all screws are correctly locked.

6) After the running-in period, do a check of the drive wheels each three months as

given above. If faults show during this period, repair them.

7) If you hear unusual noises in the area of the gear train, you must find the cause.

Replace defective drive wheels as soon as possible to prevent damage to

adjacent drive wheels.

8) Do the inspection given above one time each year when the drive wheels have

operated correctly for between 6000 hours and 8000 hours.

To do checks of the clearances and tooth marks, you must tighten the tie rods and

elastic studs of the main bearings.

2017

Summary of Contents for X35-B

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 16: ...Intentionally blank ...

Page 34: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 60: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 2 6 WCH03791 2017 ...

Page 61: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 3 6 WCH03791 2017 ...

Page 62: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 4 6 WCH03791 2017 ...

Page 63: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 5 6 WCH03791 2017 ...

Page 64: ...Maintenance 0352 1 A1 Winterthur Gas Diesel Ltd 6 6 WCH03791 2017 ...

Page 68: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 82: ...Intentionally blank ...

Page 85: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 96: ...Intentionally blank ...

Page 112: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 138: ...Intentionally blank ...

Page 154: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 180: ...Intentionally blank ...

Page 182: ...Maintenance 2728 1 A1 Winterthur Gas Diesel Ltd 2 5 6 Lift housing from the valve spindle 4 ...

Page 186: ...Intentionally blank ...

Page 190: ......

Page 204: ...Intentionally blank ...

Page 211: ...Intentionally blank ...

Page 216: ...Intentionally blank ...

Page 224: ...Intentionally blank ...

Page 228: ......

Page 229: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 270: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 294: ...Intentionally blank ...

Page 298: ...Intentionally blank ...

Page 302: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 328: ...Intentionally blank ...

Page 344: ...Intentionally blank ...

Page 368: ...Intentionally blank ...

Page 374: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 396: ...Intentionally blank ...

Page 407: ...Intentionally blank ...

Page 426: ...Intentionally blank ...

Page 442: ...Intentionally blank ...

Page 444: ...Intentionally blank ...