MAINTENANCE

Clean

or

Before Starting

the Work Period

*

End of Work

Period

Inspect power cord for wear

Before Storing

*

NOTE:

Drain

Rinse Tanks

*

Inspect

Fan

Foam Breaker

I

I

I

Remove the

Check

the

for Damage and or wear

Clean Squeegee Blades Foam Breaker

*

*

*

Remove lint build-up

from

screen in the recovery tank well.

Remove tank lid and allow recoverv to

between uses.

Raise Squeegee Assembly

I

I

I

*

*

Inspect Tanks and Hoses

Inspect all Motors for Carbon

Motor Brush wear.

*

*

Check Solution Strainer

I

I

I

Check Casters Wheels for proper lubrication

I

2.

2.

Details on these maintenance items can be found on the following pages.

This cable will lay on wet surfaces. To prevent electrical shock immediatly

replace cords with frayed or cracked insulation.

Periodically inspect the recovery tank and decontaminate if necessary,

using a Hospital Grade

or a

7-70

bleach to water solution.

Wastewater should be disposed of properly.

Occasionally check in line filter screen, rinse with hot water if necessary.

Frayed or cracked hoses should be replaced to avoid vacuum or solution

pressure loss.

3.

4.

LUBRICATION:

The following symbols are found throughout the manual indicating the items

requiring lubrication:

Apply Grease

Use Spray Lubricant.

Thread Locker (Red or blue).

EXAMPLE:

Use Anti-Seize when repairing.

98447 7/1/97

7

Summary of Contents for TRIDENT COMPACT TC20E

Page 12: ...TANKS AND FRAME 22 I 2 REAR VIEW TC20E 98447 12 01 99...

Page 14: ...SQUEEGEE ASSEMBLY A 58 7 35 l l SQUEEGEE SUB ASSEMBLY 35 t v 19 7 9 74 TCPOE 98447 1I l 1 99...

Page 16: ...VALVEGROUP 8 FROMSOLUTIONTANK 10 SOLUTIONDRAIN HOSE w Detail A 16 TCPOE 98447 3 26 98...

Page 18: ...SCRUBDECKASSEMBLY 23 I 18 TCPOE 98447 3 26 98...

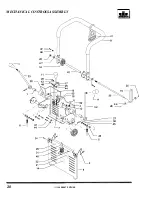

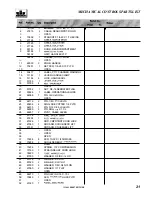

Page 20: ...MECHANICAL CONTROLSASSEMBLY n 1 1 37 44 47 32 44 9 26 Q ____ 20 TCPOE 98447 03 13 00...

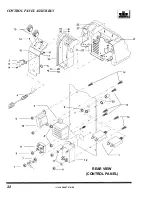

Page 22: ...CONTROLPANEL ASSEMBLY 21 12 REAR VIEW CONTROL PANEL 22 TC20E 98447 2 4 99...